Medical device packaging requirements in the U.S. are rigorous. And it makes…

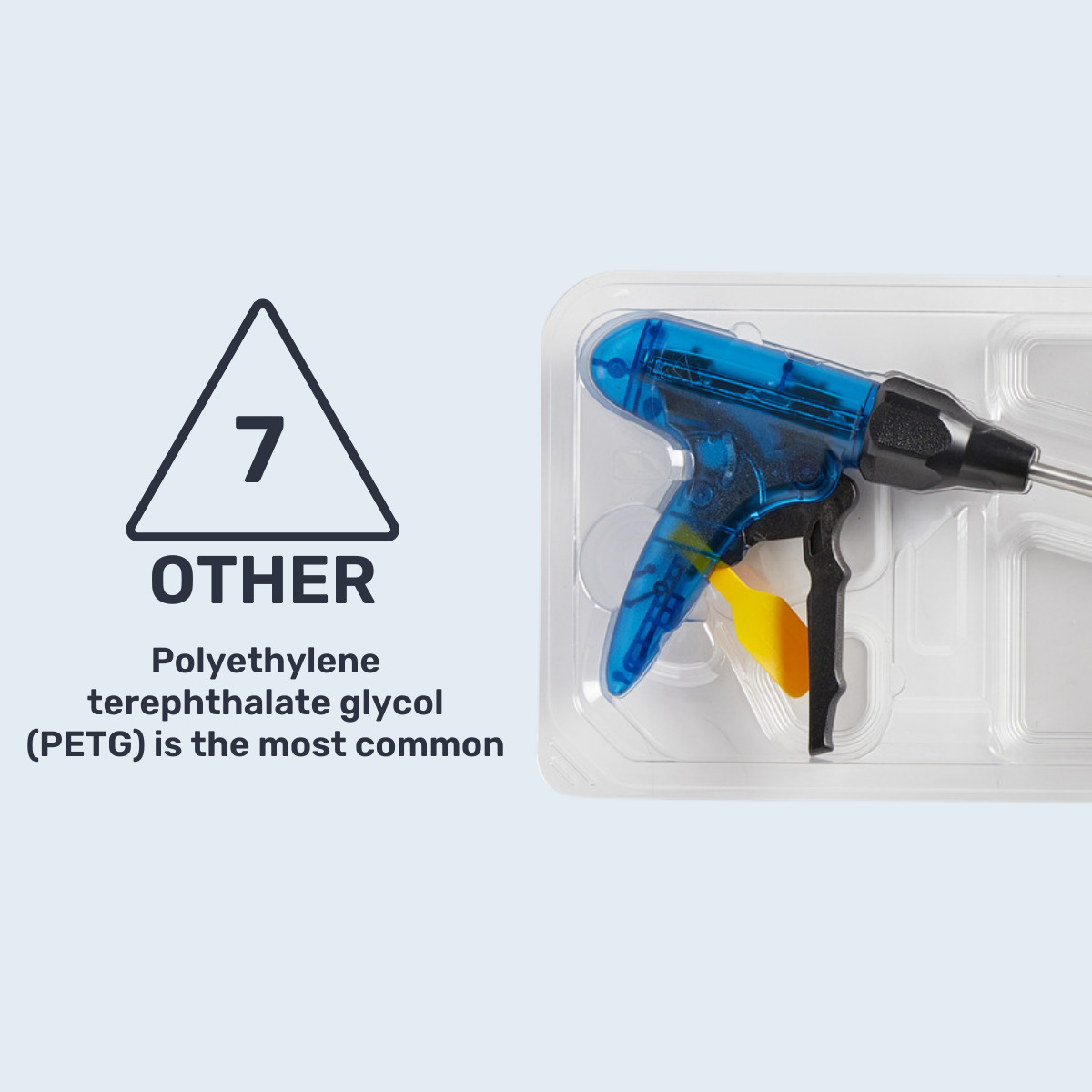

Welcome to Plastic Ingenuity’s blog series on packaging polymers! In this series, we will explore the different types of polymers used in packaging and their properties, applications, and environmental impact. We will also discuss the latest developments in sustainable packaging and how the industry is evolving to meet the growing demand for circular solutions. Join us as we dive into our seventh, and final installment, in our series with material #7: Other – although Resin ID Code #7 is used to identify any plastic type that does not fit into the #1 through #6 categories, we will use this space to highlight PETG given its prevalent use in packaging applications.

PETG (polyethylene terephthalate glycol) is a type of plastic that is widely used for packaging applications. This versatile polymer can withstand the rigors of most sterilization methods, making it ideal for use protecting medical devices. It can also weld to itself using conventional heat-sealing methods, making it ideal for retail applications requiring that function. Its high level of clarity makes it a viable shatter-proof substitute for glass jars.

Here are some common applications for PETG packaging:

▪️ Food packaging: PETG is commonly used for food packaging, such as containers for baked goods, produce, and dairy products. It is safe for use with food and can be easily thermoformed to create a variety of shapes and sizes.

▪️ Medical packaging: PETG is often used for medical packaging, such as vials, ampoules, and syringe barrels. It is non-reactive and can withstand sterilization processes, making it ideal for use in medical applications.

▪️ Cosmetics packaging: PETG is used for packaging cosmetics, such as jars, bottles, and tubes. Its transparency allows the product inside to be visible, and it can be easily decorated with labels and other graphics.

▪️ Electronic packaging: PETG is used for electronic packaging, such as enclosures for circuit boards and other components. It is resistant to heat and chemicals, making it ideal for protecting sensitive electronic devices.

▪️ Retail packaging: PETG is often used for retail packaging, such as blister packs, clamshells, and hang tags. Its clarity and ability to be printed on make it an attractive option for showcasing products in retail environments.

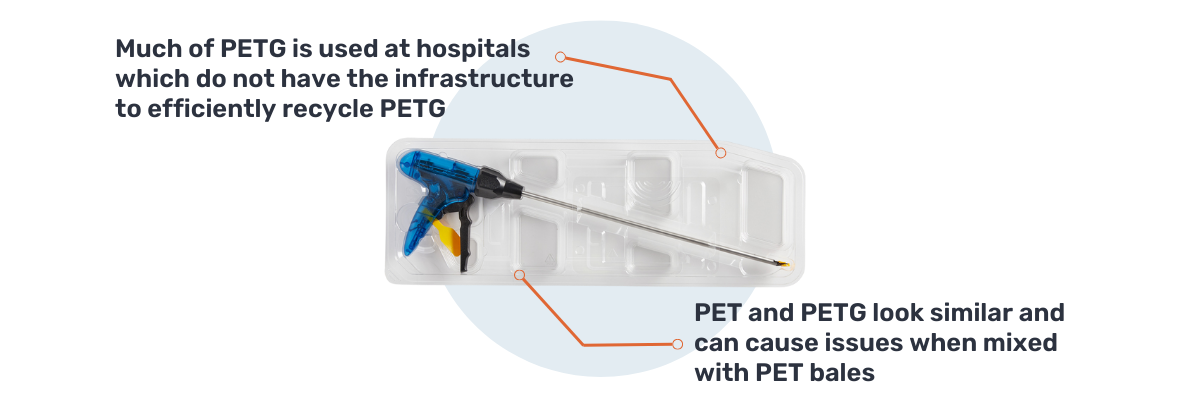

The main drawback of PETG is that is not recycled today at scale. A PETG package looks like a PET package on a manual sorting line. If too many PETG packages are sorted into a PET bale, it can cause issues with recycling the PET.

PETG packages are commonly used in healthcare facilities, like hospitals. Although a majority are not contaminated with bio-hazard materials, hospitals lack the infrastructure to efficiently collect these for recycling.

Organizations are turning to advanced recycling methods to recycle PETG. Those technologies could play a key role in increasing PETG recycling. Also, organizations like the Healthcare Plastics Recycling Counsel are galvanizing methods to efficiently collect these plastics for recycling.

In conclusion, we have explored various aspects of packaging polymers through this blog series. We started by understanding the importance of packaging in the modern world and how polymers have become the material of choice for packaging applications.

Overall, packaging polymers play a crucial role in our daily lives and are continuously evolving to meet the changing needs of consumers and the environment. As we move towards a more sustainable future, it is essential to continue exploring new and innovative ways to reduce the environmental impact of plastic materials.

For more information about sustainability in the plastics industry, visit www.plasticingenuity.com/sustainability