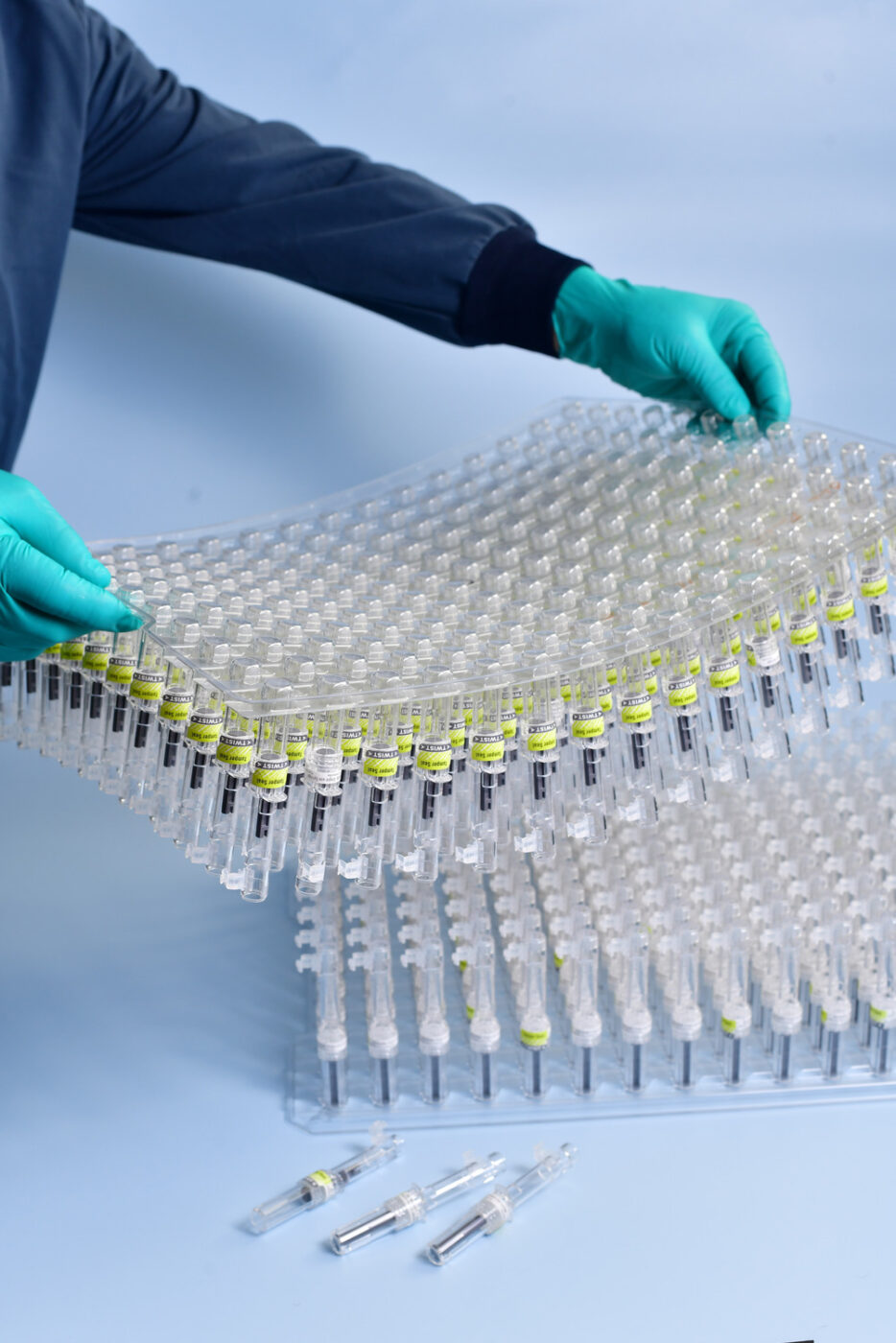

In the fast-paced world of healthcare and pharmaceuticals, thermoformed automation trays, also…

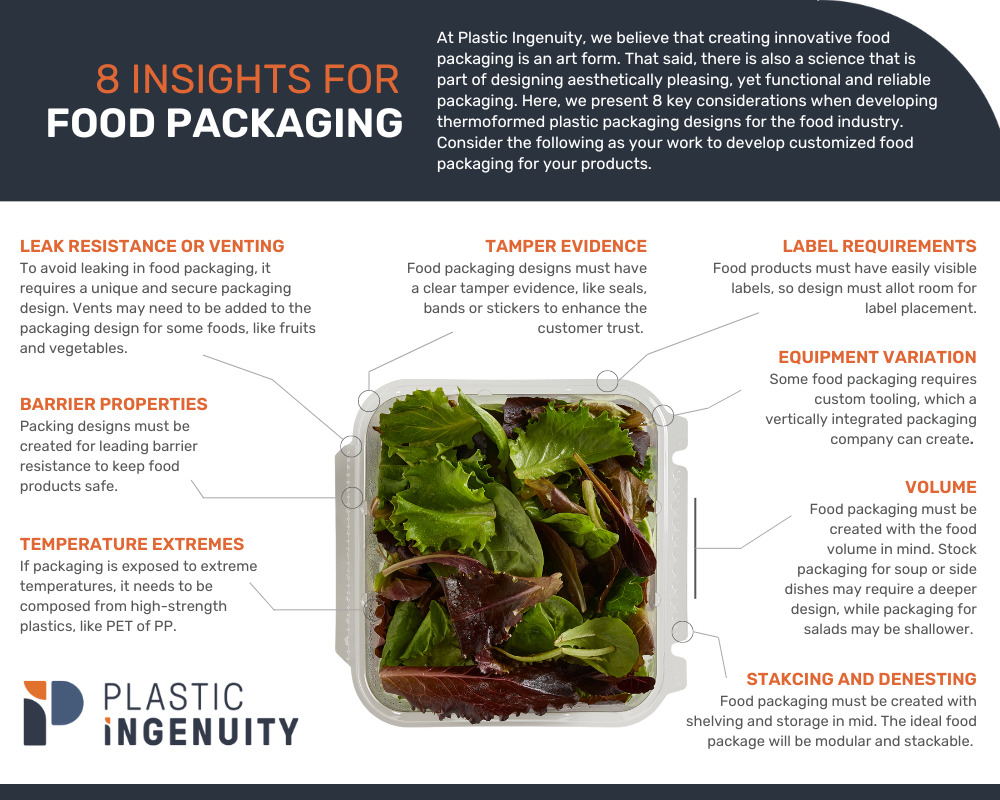

When you think of the things that make a package stand out on the shelves, you probably have some go-to elements like color, size and label. With food packaging, however, there are some other factors that need to be considered when designing a package. Attractive packaging is one thing, but food packaging needs to address the unique needs of the food industry, such as:

At Plastic Ingenuity, we want your business to succeed as much as you do, and that’s why we’re dedicated to helping our clients determine the best ways to design quality food packaging.

We considered all aspects of what the ideal food package should feature, and with that information, we created this useful image that you can use as a guide when coming up with ideas and designs for your products’ thermo-packaging. Some things you may not have thought of include whether the package will need vents for air circulation (necessary for fruits and vegetables to help prevent rotting), leak resistance, how the product will stack on shelves, and more.

And we practice this thinking on every project. See how we applied the 8 factors for food packaging success for Sargento Foods with a breakthrough new package design in this case study. We’re proud of our contribution to this AmeriStar award-winning quick serve snack product.

When you need attractive and highly functional plastic packaging for your food products, contact Plastic Ingenuity.