What Quality Means at Plastic Ingenuity

Quality Assurance is of utmost importance to Plastic Ingenuity, as it centers on understanding our customer’s processes and requirements. By recognizing each customer’s specific needs, we can tailor our products, services, and testing to meet and exceed their expectations.

A robust Quality Assurance system ensures that our packaging solutions are consistent, reliable, and tailored to optimize their processes, enhancing efficiency and cost-effectiveness. Through continuous monitoring, analysis, and improvement, we pledge that our products align seamlessly with our customers’ unique demands, fostering long-lasting partnerships built on trust and satisfaction.

The Importance of Stringent QA Standards

The importance of QA standards cannot be overstated when customers are auditing a plastic manufacturing company. By proudly stating, “We are ISO 9001 and 13485 certified,” Plastic Ingenuity can showcase its commitment to quality, efficiency, and customer satisfaction. These stringent standards are seamlessly integrated into our quality processes, incorporating vital elements such as Good Documentation Practices, In-Process, Final Inspection, and Calibration.

These measures ensure that every aspect of the production process adheres to the highest levels of quality and safety. By complying with these internationally recognized standards, Plastic Ingenuity demonstrates its dedication to delivering products that meet the highest industry benchmarks, instilling confidence in our customers and reinforcing our position as a leader in the industry.

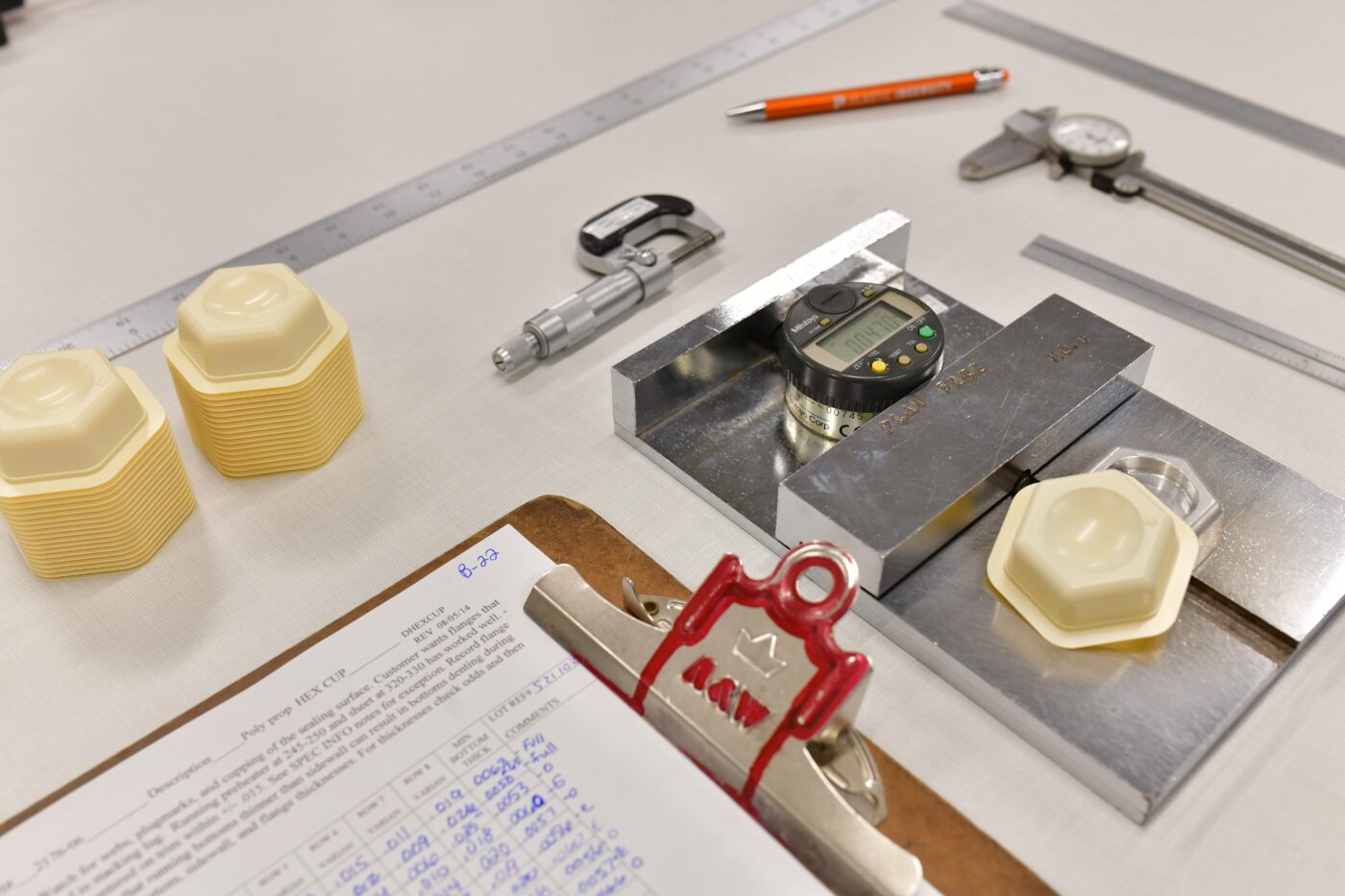

Having unique and specialized quality processes is a significant advantage for Plastic Ingenuity. We can fabricate custom features and equipment thanks to our vertical integration and an in-house design team and shop. This capability allows us to establish tailored testing methodologies for every critical aspect concerning product quality. By having complete control over the entire process, we ensure that our products meet the highest standards and comply with the most stringent quality requirements.

We Check and Recheck our Quality

Here are just a few of the quality checks we provide:

- Minimum thickness

- Flatness/warp and bow

- Clarity

- Trim Centering

- Snap forces, opening and closing forces

- Dimensionals using our Coordinate Measuring Machine (CMM) or 2D Vision System

- Seal integrity testing – seal peel force and burst testing

- Form detail

- Stress analysis of formed parts

- Attribute inspections (trim hair, particulate, seal surface inspection for scratches, scuff marks, etc.)

Additionally, we can create unique tests for specific customers. For example, we recently constructed specific tests for Tyson Hillshire Foods addressing a perforation in the package. We developed specialized flex testing and perforation break testing to accommodate their requests. Custom fixtures were designed in Engineering, resulting in the production of millions of high-quality packages. Our QA department routinely develops quality tests specific to our customers’ needs.

Quality Backed by Certification

By encouraging all QA Inspectors to pursue the Certified Quality Technician certification through the American Society for Quality (ASQ), Plastic Ingenuity ensures a standardized and high level of expertise among its team. This certification equips inspectors with comprehensive knowledge and practical skills, enabling them to analyze and address quality-related issues effectively.

Equipped with a deep understanding of tools and concepts such as Statistical Process Control, our QA Inspectors can conduct more accurate and data-driven evaluations, improving efficiency and reducing defects. Investing in specialized quality assurance education enhances our ability to deliver top-notch packaging solutions that meet all criteria consistently.