In the fast-paced world of healthcare and pharmaceuticals, thermoformed automation trays, also known as work-in-process (WIP) trays, are essential tools. These trays are designed to integrate seamlessly into automated equipment, ensuring the protection of sensitive and high-value components. This blog post will explore the key considerations for designing custom thermoformed automation trays to optimize efficiency.

Product Positioning and Layout

The journey to creating effective thermoformed WIP trays begins with the orientation and configuration of the product within the tray. Products can be oriented horizontally or vertically, but the configuration is more complex. Rotating the product in the X, Y, or Z direction can impact tray capacity, material options, and product protection features. These changes may also affect downstream processes like stacking and cartoning. It’s crucial to weigh all potential benefits and drawbacks.

Tray Size and Dimensions

Determining the size of automation trays involves several factors, including the number of parts per tray and the pitch between parts. Automated equipment may also dictate acceptable tray length and width. Additionally, matching the pitch of the end-of-arm tooling, such as suction cups or grippers, and maintaining dimensional consistency is vital. The pitch width will change if manual finger picks are needed for loading or unloading the trays. The equipment’s maximum capacity to pick components also influences WIP tray sizing. For instance, If a robot picks 8 components simultaneously, the tray should be designed in rows of a multiple of 8, not 20.

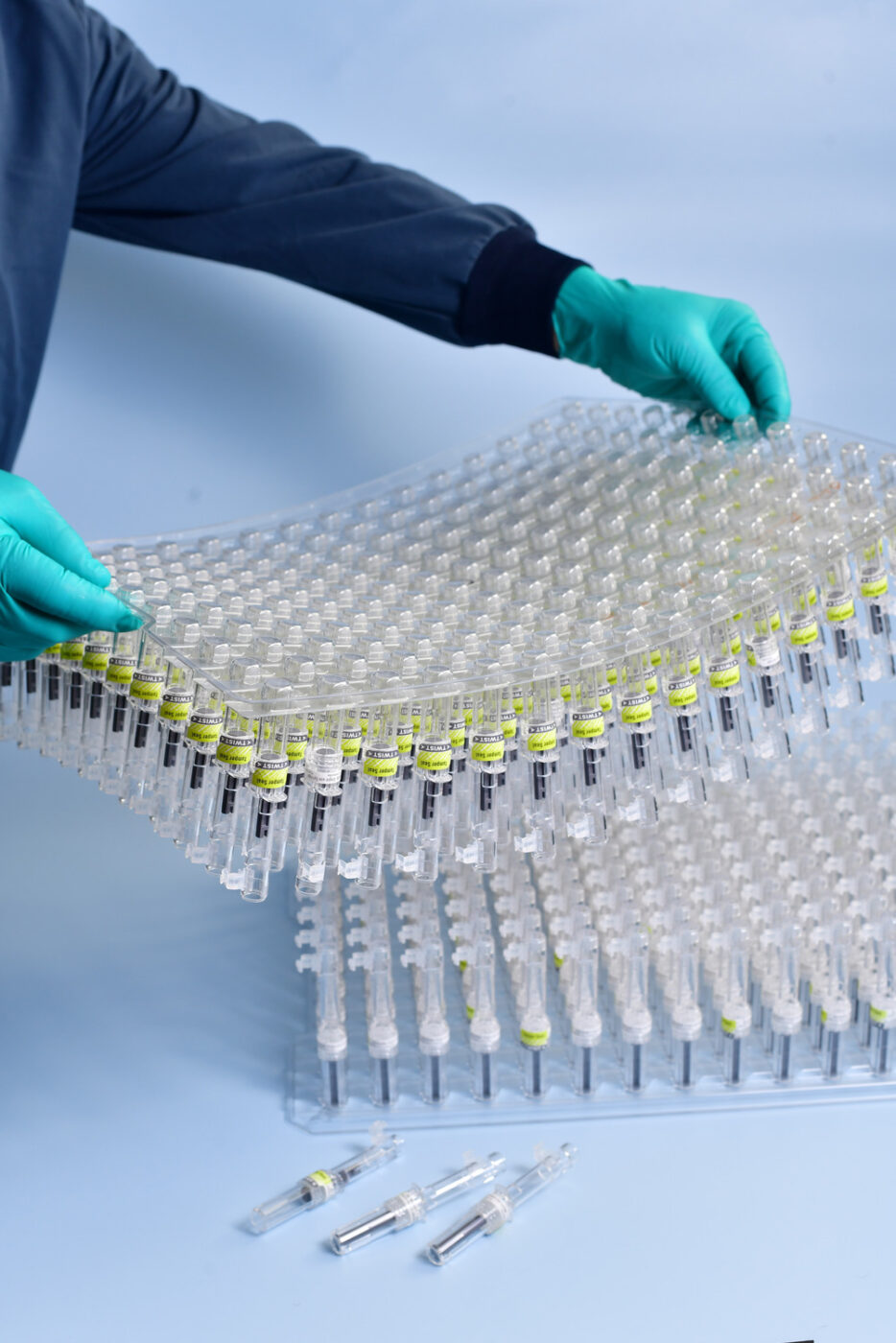

Ensuring Component Fit and Protection

Properly designed WIP trays provide the necessary protection for delicate healthcare product components. This includes ensuring clearance from other components, sections of the tray, and other trays. Trays can be designed with contour or snap-fit cavities. Both feature cavities shaped like the product or components, but snap-fit trays include undercuts that firmly hold the product in place. Fitting components to the mold side of the part removes varying material thickness across the tray, providing a more consistent fit.

Maintaining a consistent thermoforming process is also crucial for cavity fit. Critical features of the tray will require quality checks throughout the supplier’s production run to ensure the tray functions properly within the automated manufacturing system.

Efficient Tray Stacking

Carton fit, automation constraints, or weight limits usually determine the total stack height of multiple loaded trays. Automation equipment dictates whether loaded trays can be rotated 180° for stacking or if trays must be stacked without rotation. Aggressive undercuts are required for trays that cannot rotate for stacking, increasing tool complexity. Snap-fit cavity trays generally stack higher due to the snap features, while contour-fit cavity trays typically decrease stack height for greater packing density and reduced shipping rates. However, they also require an empty tray to act as a lid or a secondary flat lid to be created.

Automation trays are repeatedly stacked and unstacked throughout the manufacturing, packing, and shipping stages. Designing trays with a dissimilar corner helps operators easily verify tray orientation within the stack. Another way to optimize by design is to downgauge materials where possible, improving the sustainability of automation trays. Thorough prototype testing must confirm that the final tray can withstand the different forces encountered during manufacturing, packaging, and transport.

Integrating with Automation Systems

Some healthcare and pharmaceutical products might be manufactured across multiple facilities. In such cases, thermoform design engineers must understand the different processes required to build the product and the specifications of the automated system. Depending on their complexity, certain products or production methods may require multiple automation trays.

Collaboration is required at all stages of the supply chain, including the device manufacturer, automation fabricator, and thermoform supplier, to ensure smooth integration of custom WIP trays with automation systems. An optimized automation process supports operational efficiencies and improves customer experience, ultimately fostering long-term business partnerships.