This post was written by Jeremy Whitish – Technical Sales Representative

From design considerations, to sustainability, to commercial goals, there are a multitude of considerations to address when developing the optimal packaging solution. At-home diagnostic packaging is a clear example of this since many factors can affect the design and proper material choice. How will your packaging be used? What will your package contain? Who will be using it? These are all questions we need to ask before the development process begins.

Before your product even gets to the end-user, there are a variety of questions to consider. Is the package loaded by hand, or is there automation equipment for this process? Is equipment necessary and established? Our team will design solutions with these factors in mind, while also considering options for robot picking, clamping, etc….

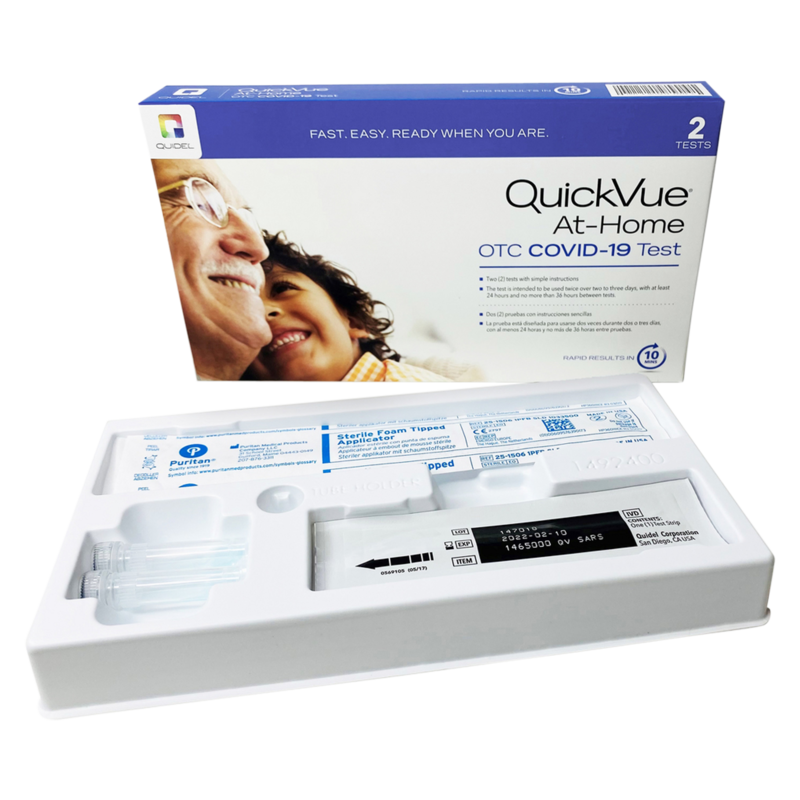

Do aesthetics influence your packaging decisions? Typically, with a consumer product, it will. White HIPS is a commonly considered material, and one that accepts many other color options. However, if transparency is desired, we would look closely at PET or PETG alternatives. We would also consider whether it will be a sealed, a standalone product, or something that is boxed.

One of the main drivers of material selection is sterility requirements. Although other materials can be used, sterile applications are dominated by PETG options. This material is more expensive than other materials that have been mentioned, but many times the initial extra cost is less than what may occur down the road. On top of its superior sterilization properties, PETG is also a strong material and delivers a robust shelf life.

We must also consider the end-user. It is not uncommon for the patient of an at-home device to be elderly, and/or have physical deficiencies. Excess seal strength, challenging product removal force, and inadequately sized finger picks could all result in unwanted experiences for many with physical impacts.

Additionally, sustainability in packaging is a significant factor with at-home care packaging versus something that ends up in a hospital, clinic, or lab. Consumers are looking for sustainable options more than ever.

They often choose, and even pay more for, a solution they perceive as “earth-friendly”. This shift has resulted in a pivot from materials such as HIPS, to materials that are more commonly recycled, such as PET. Although most plastic can be recycled in some fashion, few recycling programs have the infrastructure to handle a wide variety of materials.

Although patient safety is the top priority, and sustainability is a high priority, cost continues to be a major factor for most projects. Typically, our material selection will be determined by the specific criteria of each product, but there are other factors that may reduce cost. Our design team optimizes the package footprint from the start, but there are often improvement opportunities, including downgauging, once process capabilities have been proven, and repeated. Along with this, if virgin material is not required, we can look at using post-industrial material from within our operation to further reduce cost.

A wide variety of considerations need to come together to produce a safe, cost-effective package in a timely manner. Plastic Ingenuity has worked with diagnostic packaging for nearly two decades. Our wide variety of experience (average design engineering tenure of over 25 years) provides us with a diverse knowledge and skill set that helps us solve nearly any challenge you have.