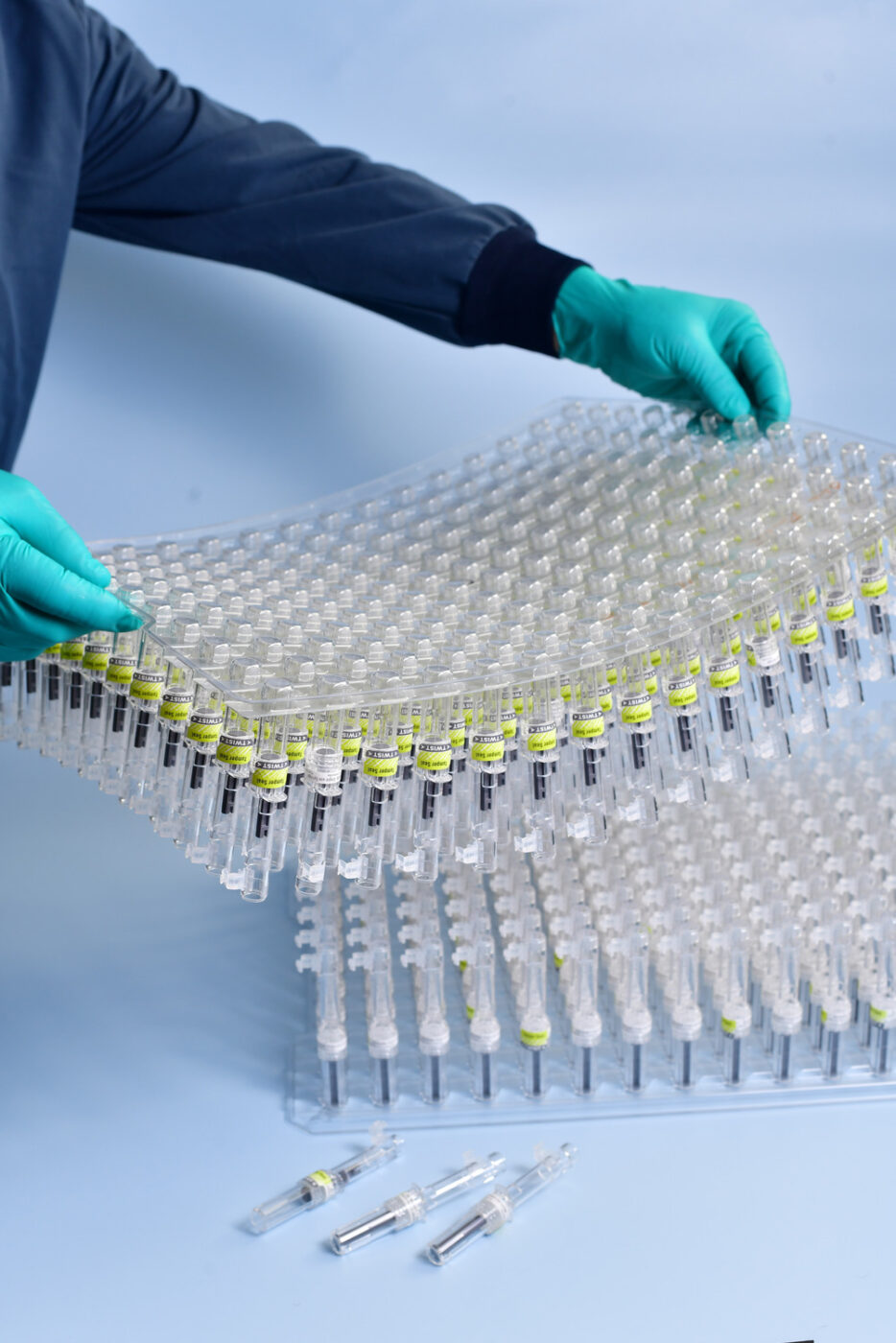

In the fast-paced world of healthcare and pharmaceuticals, thermoformed automation trays, also…

Many types of plastic materials are available to produce packaging. When you need to create a design to package your products, you may soon discover that two plastic materials are commonly used: PET and PVC. At Plastic Ingenuity, we have clients ask us which plastic materials prove to be most advantageous for their thermoformed packaging designs. Here, we’ve outlined explanations for these two plastics, as well as which proves to be the most beneficial to help you determine which to use.

PET, or polyethylene terephthalate plastics is one the most widely used plastics for thermoforming. The material is molded into the designated shape, and then dried for increased resistance. The plastic is used to produce food containers, beverage bottles, synthetic fibers and more. PET is the most common plastic for thermoforming packaging designs because of its high-strength barrier that can resist outside tampering or other elements.

PVC plastic, or polyvinyl chloride, is a rigid plastic designed to withstand harsh impacts and extreme temperatures. The material is most commonly used when creating cables, roofing materials, commercial signage, flooring, faux leather clothing, pipes, hoses and more. PVC plastic is created through suspension polymerization to produce a hard, rigid structure.

The following are the biggest benefits that PET plastic provides:

For more information about PET, as well as how you can utilize it in your plastic packaging design, get in touch with the team at Pl today. For additional packaging news and information, check out our Facebook.