The Challenge

Repurposing Plastic Waste While Reducing Greenhouse Gas Emissions

A global pharmaceutical company aspired to repurpose plastic waste for beneficial reuse or recycling, as well as engage with key suppliers in their value chain to drive greenhouse gas (GHG) emission reductions. The healthcare industry is an underutilized waste stream for recycled material, and increasing access to these sources will help reduce virgin plastic usage and improve the circularity of healthcare plastics.

The Process

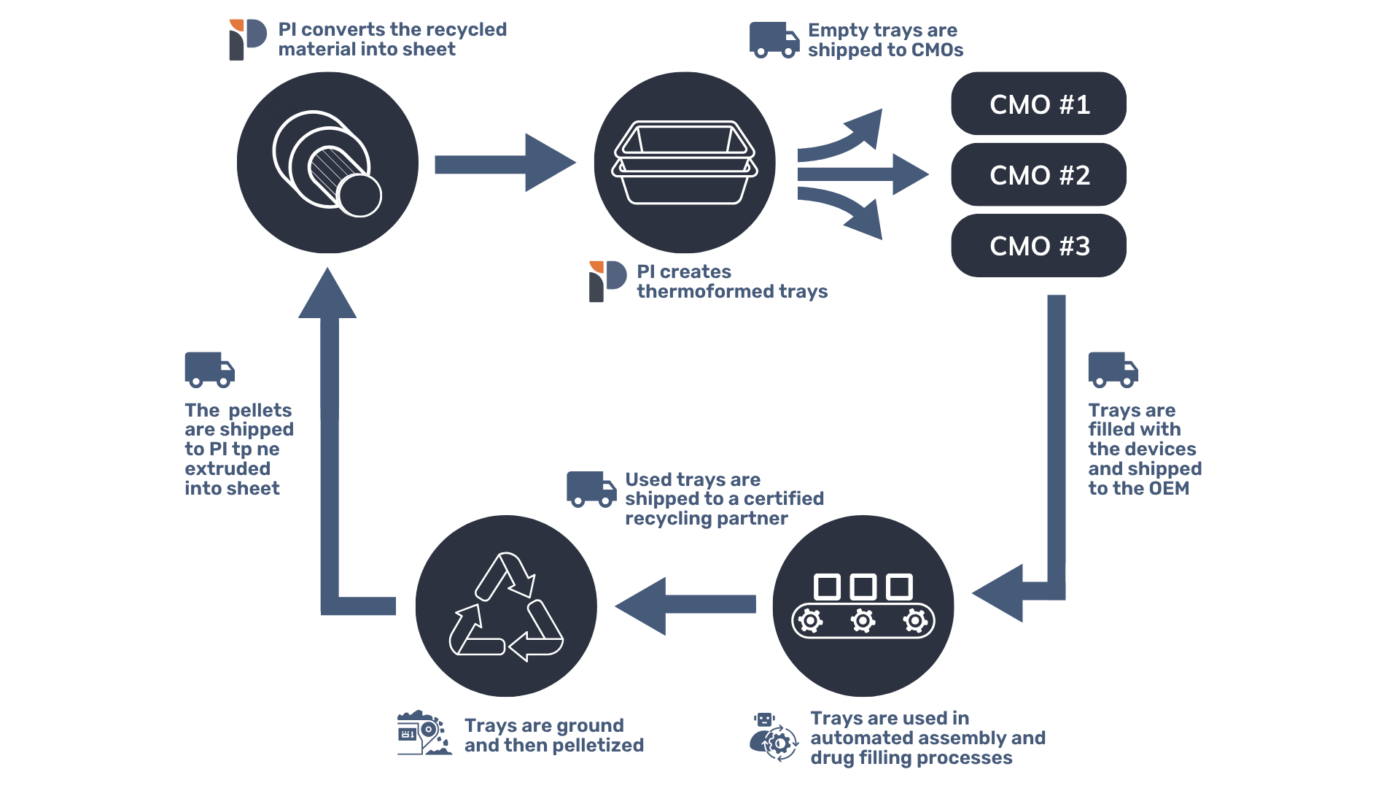

Creating a Custom Take-Back Program

Plastic Ingenuity partnered with the pharmaceutical company to begin incorporating 50% recycled high impact polystyrene (HIPS) resin into their thermoformed trays. Additionally, Plastic Ingenuity helped establish a closed-loop recycling system where the trays, now including 50% recycled material, were shipped directly to contract manufacturing organizations (CMOs) to be filled with devices, then shipped to the pharmaceutical company to finalize the product. The used thermoformed trays were then shipped to a recycling partner that ground the trays into flake and pelletized the material. The pellets were shipped back to Plastic Ingenuity to be incorporated into the extrusion process to make new thermoformed trays and continue the cycle.

The Solution

Circularity with a Lower Environmental Impact

A carbon footprint analysis of the pharmaceutical company’s take-back program demonstrated significant improvement, with a 41% annual reduction of carbon dioxide equivalent (CO2e), or 17,338 metric tons of CO2e avoided. Additionally, they displaced 2,009 metric tons of virgin plastic by incorporating 50% recycled material in the thermoformed trays.

The Results

A Resounding Success

of virgin plastic material saved

of CO2e avoided

Gas-powered cars per year removed