The fourth edition of Plastic Ingenuity’s Thermoform Circularity Report marks a significant…

Toolkit

EPR legislation has significant impacts on thermoformed packaging, driving advancements in sustainable practices. EPR policies hold producers accountable for the lifecycle of their products, promoting recyclable packaging designs, plastic source reduction, and increased post-consumer recycled (PCR) content. These policies encourage manufacturers to innovate, creating materials and packaging systems that are easier to recycle and integrate PCR. By incentivizing sustainable production, EPR supports a shift towards a circular economy, aiming to minimize waste and reduce reliance on virgin plastics, thus reshaping the future of thermoform packaging.

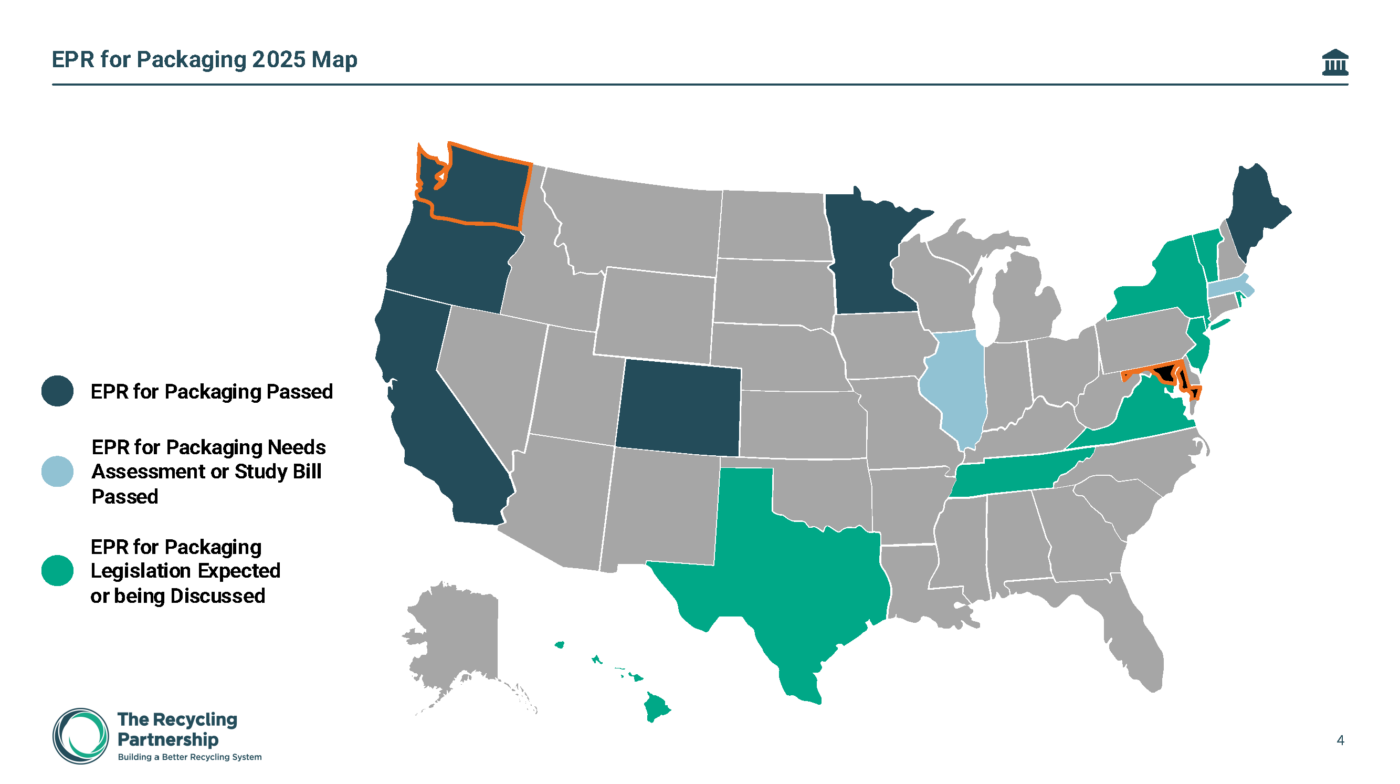

As of mid-2025, Extended Producer Responsibility, or EPR for short, for packaging is gaining significant traction across the United States. Seven states—Maine, Oregon, California, Colorado, Minnesota, Maryland, and Washington—have enacted EPR laws, with Maryland and Washington joining the list in May 2025. These laws shift the financial and operational responsibility for packaging waste management from municipalities to Producers, aiming to improve recycling rates and reduce environmental impacts.

The implementation timelines and requirements vary by state, but collectively, these initiatives mark a substantial move toward a circular economy. As a result, approximately 20% of the U.S. population now resides in states with active packaging EPR legislation.

Non-compliance is not an option. Non-compliant Producers may face significant monetary fines. For example, California’s EPR statute allows for penalties of up to $50,000 per day per violation. States may prohibit the sale of products in non-compliant packaging, effectively barring a company from entering or remaining in that market. In some cases, repeated or severe non-compliance can result in suspension or loss of business licenses related to packaging distribution.

Producers can accelerate compliance by concentrating on core tenets, despite differing state requirements. In this toolkit, we’ll cover three core tenets of packaging EPR: Design for Recyclability, Source Reduction, and Post-Consumer Recycled Content. Although the information contained within is not legal advice, our goal is to equip you with practical strategies and tools to meet regulatory requirements while advancing your sustainability goals. If your company qualifies as an obligated producer under EPR laws, be sure to register with the designated producer responsibility organization (PRO) in each applicable state.

| Key EPR Tenent | Description | Current State for Thermoforms | Pathway to Compliance |

|---|---|---|---|

| Recyclable Packaging | In California, all covered packaging must meet recyclability standards, or producers lose the ability to make recyclability claims by 2025. Stricter requirements are set for 2032; non-compliance by then could result in sales bans and civil penalties. California has ambitious recycling rate targets for covered materials: – 30% by 2028 – 40% by 2030 – 65% by 2032 | Non-bottle PET and Polypropylene containers, like thermoforms, both have a national residential recycling rate of 8%. In California, non-bottle PET containers have a residential recycling rate of 14% and Polypropylene containers have a residential recycling rate of 13%. Residential recycling rate data is derived from The Recycling Partnership’s 2024 State of Recycling Report. | Pathway to Transition to recyclable materials. For example, shift from PVC or PS to PET. Follow design for recyclability guidelines such as the Association of Plastic Recycler’s Design Guide or How2Recycle label framework. To aid in design for recycling mandates, Plastic Ingenuity evaluates every thermoform design for recyclability requirements. |

| Plastic Source Reduction | California mandates a reduction in plastic use by: – 10% by 2027 – 20% by 2030 – 25% by 2032 Only 8% of the source reduction can come from post-consumer recycled content. At least 10% of the source reduction must come by shifting to reuse or refill by 2032. These reduction targets aim to decrease unnecessary packaging and limit the use of virgin materials. | The baseline year for source reduction reporting is 2023. However, brands may receive credit for down-gauging efforts dating back to 2013 with proper evidence. Brands are gathering part weight data and legacy evidence of downgauging efforts. | Maximize post-consumer recycled materials when possible. Plastic Ingenuity offers PCR options for PET, PP, and HDPE. Identify down-gauging opportunities to reduce material usage. Document PCR and minimization efforts for reporting. Plastic Ingenuity’s Sustainable Packaging Assessment provides impact data related to increases in PCR and down-gauging efforts. |

| PCR Usage | States and countries with active PCR mandates for non-bottle rigids are New Jersey, California, and Canada. New Jersey’s minimum PCR content law came into effect in 2024: – 10% PCR content in 2024 – 50% PCR by 2036 California will begin requiring PCR in 2027: – 10% by 2027 – 20% by 2030 – 25% by 2032 Canada will begin requiring PCR starting in 2025: – 20% PCR starting in 2025 – Increases to 50% by 2030 | Sources for PCR PET are readily available. Sources for PCR polypropylene are growing. However, there is concern from brands about the availability of PCR supply to meet escalating demand. Due to stagnant domestic recycling rates, imports of recycled materials have increased to meet rising demand, but concerns remain about the credibility of PCR coming from offshore sources. | Evaluate opportunities to maximize PCR wherever possible. Plastic Ingenuity provides a range of recycled material options for PET, HDPE, and polypropylene packaging. Our materials portfolio includes FDA No Objection Letter (NOL) status for food-grade applications, with sources from both mechanically and advanced recycled processes, supported by ISCC PLUS mass balance allocation. Third-party certifications for PCR materials are available to ensure credibility and transparency of recycled material sources. |

Understanding Packaging EPR: What Brands Need to Know WATCH NOW

Designing Packaging for Recyclability WATCH NOW

Top EPR Questions Answered: What Brands Need to Know About Compliance WATCH NOW

Ensuring Recyclability through APR Critical Guidance Program

PI Informational Handouts

External Resources and Sources

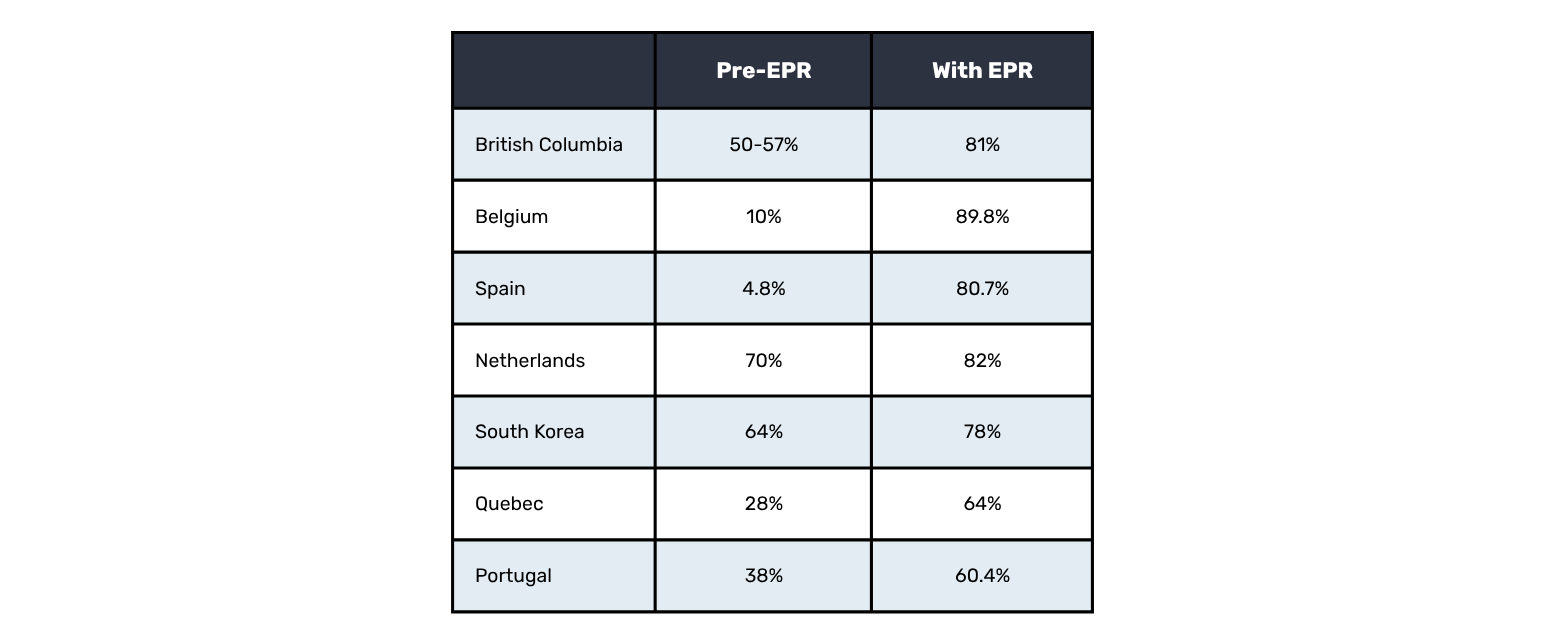

The Recycling Partnership studied seven EPR programs around the world and found that the policy substantially increased collection and recycling of target materials across the board. Recycling rates climbed as high as 90% after EPR implementation.

No, EPR is not a tax—it’s a regulatory framework that requires producers to take financial and operational responsibility for managing their products’ end-of-life impacts. Unlike a tax, which goes into a state’s general fund and can be used for any purpose, EPR statutes typically establish a dedicated fund where producer contributions are specifically allocated to support the program.

The fees vary from state to state. They are assessed by the Producer Responsibility Organization (PRO) based on factors such as material types, weight, recyclability, and use of recycled content. A concept called “eco-modulation” is often leveraged to incentivize more sustainable designs. A brand should consult with the PRO for specifics.

The fees cover program needs as assessed by the state regulators. These typically include recycling and waste disposal operations, recycling infrastructure investments, consumer education, and administrative costs.

This answer is nuanced since the definition of obligated producer differs in each state. The obligated producer is typically the brand owner, manufacturer, or importer that first sells or distributes packaged products in the state. Brands should consult the PRO for guidance.

A Producer Responsibility Organization, or PRO, is a third-party entity that manages the responsibilities of producers under an EPR program, such as collecting fees, coordinating recycling operations, ensuring regulatory compliance, and reporting program outcomes on behalf of its member companies. Circular Action Alliance is emerging as the PRO in many EPR states.

Each state sets its own schedule. The Oregon program is the first to launch, starting in July 2025. A phased rollout in California starts in 2025. The other states start in 2026 or later.

Non-compliant Producers may face significant monetary fines. For example, California’s EPR statute allows for penalties of up to $50,000 per day per violation. States may prohibit the sale of products in non-compliant packaging, effectively barring a company from entering or remaining in that market. In some cases, repeated or severe non-compliance can result in suspension or loss of business licenses related to packaging distribution.

Producers must report packaging data such as the types, weights, and volumes of covered materials sold in the state. They must also report how the packaging aligns with recycling guidelines and uses post-consumer recycled materials or other sustainable attributes.

There are several ways to minimize fees. These include designing for recycling, source reduction, and using post-consumer recycled materials. Producers should understand the eco-modulation incentives in each state and align packaging efforts accordingly.

Questions?

Do you have additional questions or think this information would be valuable for the rest of your team? We’re here to help! Please reach out if we can help with your sustainability goals or you would like to schedule a free Lunch and Learn.