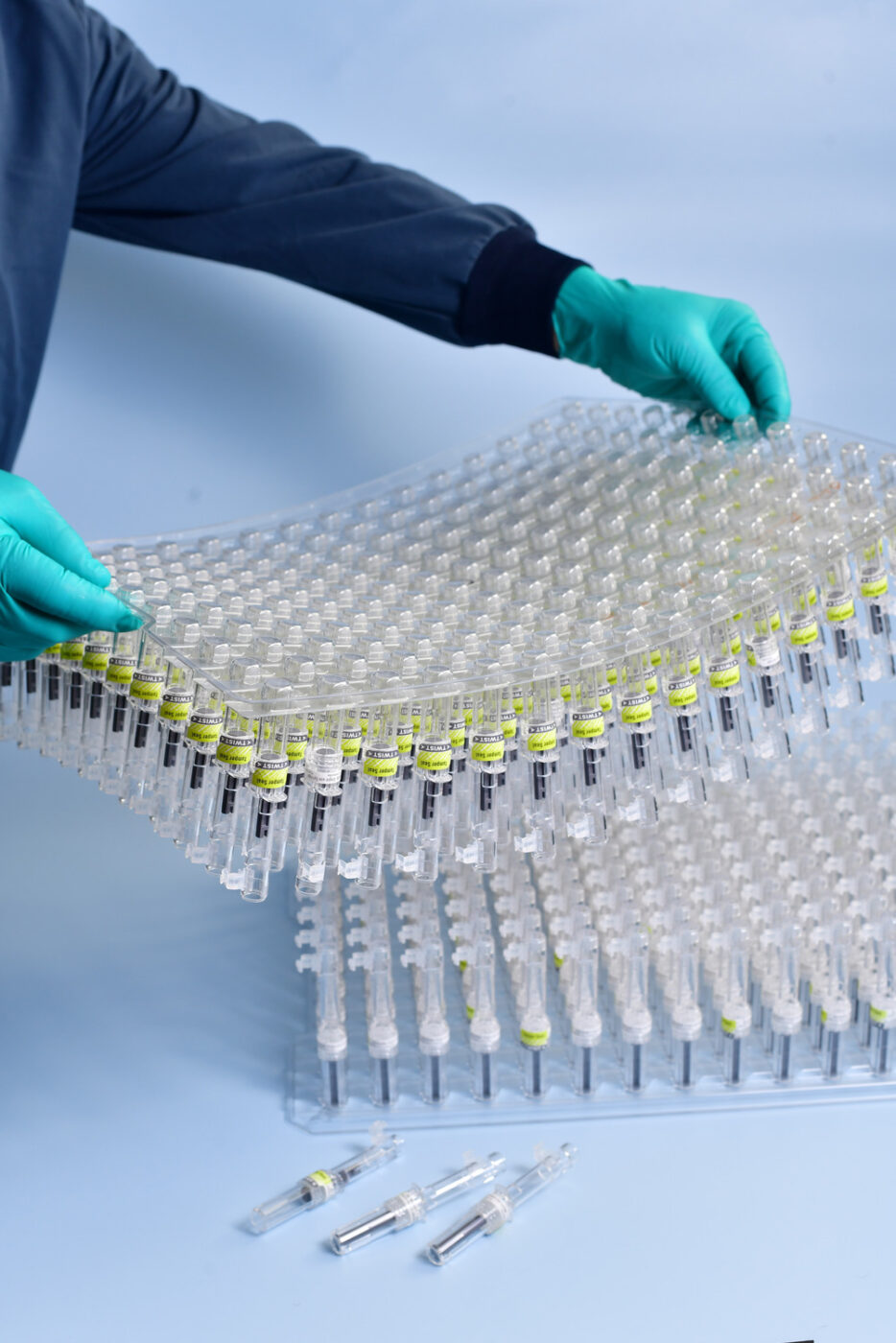

In the fast-paced world of healthcare and pharmaceuticals, thermoformed automation trays, also…

High Pressure Processing (HPP) — also known as high hydrostatic pressure (HHP) or ultra-high pressure (UHP) processing — has quickly risen in popularity within the food packaging industry.

High Pressure Processing is a pasteurization method whereby packaged food — liquid or solid — is submersed in an enclosed water bath and the water surrounding the product is brought to extreme pressure levels. The high-pressure levels reached during the HPP process inactivate harmful bacteria in the packaged product such as Listeria, E. coli, and Salmonella.

Although HPP, Retort and Aseptic packaging are all effective pasteurization methods, HPP has one significant advantage – HPP doesn’t damage nutrients or cause thermal degradation. One clear example of the difference in effects of HPP vs. traditional heat pasteurization is the difference in flavor and smell of fresh squeezed orange juice vs orange juice from the store (bottled or from concentrate).

Generally, freshly squeezed orange juice has a fresher flavor than store bought because the store bought OJ is heated prior to being bottled to neutralize harmful bacteria, thus altering the taste. With HPP, the high pressure takes care of the harmful bacteria, and the flavor of the juice is not affected.

There is a slight temperature shift in the water bath during an HPP cycle, however the water only fluctuates between ~5°C (~41°F) and ~30°C (~86°F), which results in no temperature effect on the product. (As a comparison, Retort processing reaches 110°C (230°F) to 135°C (275°F), and Aseptic reaches 91°C (196°F) to 146°C (295°F).

Because HPP is a high stress environment, choice of packaging is critical. Many companies use flexible pouches or bottles in HPP with high success. When it comes to thermoforming, the seal of the product is critical, as well as the fill volume inside the package. Ultimately, designing a package that succeeds through HPP can require multiple design iterations and trial runs.

Yes! We have experience designing and manufacturing packages that run through HPP for multiple customers. Our speed and flexibility, especially when it comes to designing and piloting parts, has proven to be a major benefit for our customers trialing packaging through HPP.

To learn about HPP packaging, download our eBook, “Avoid Food Spoilage with HPP Packaging” or Contact Us to speak to an expert.