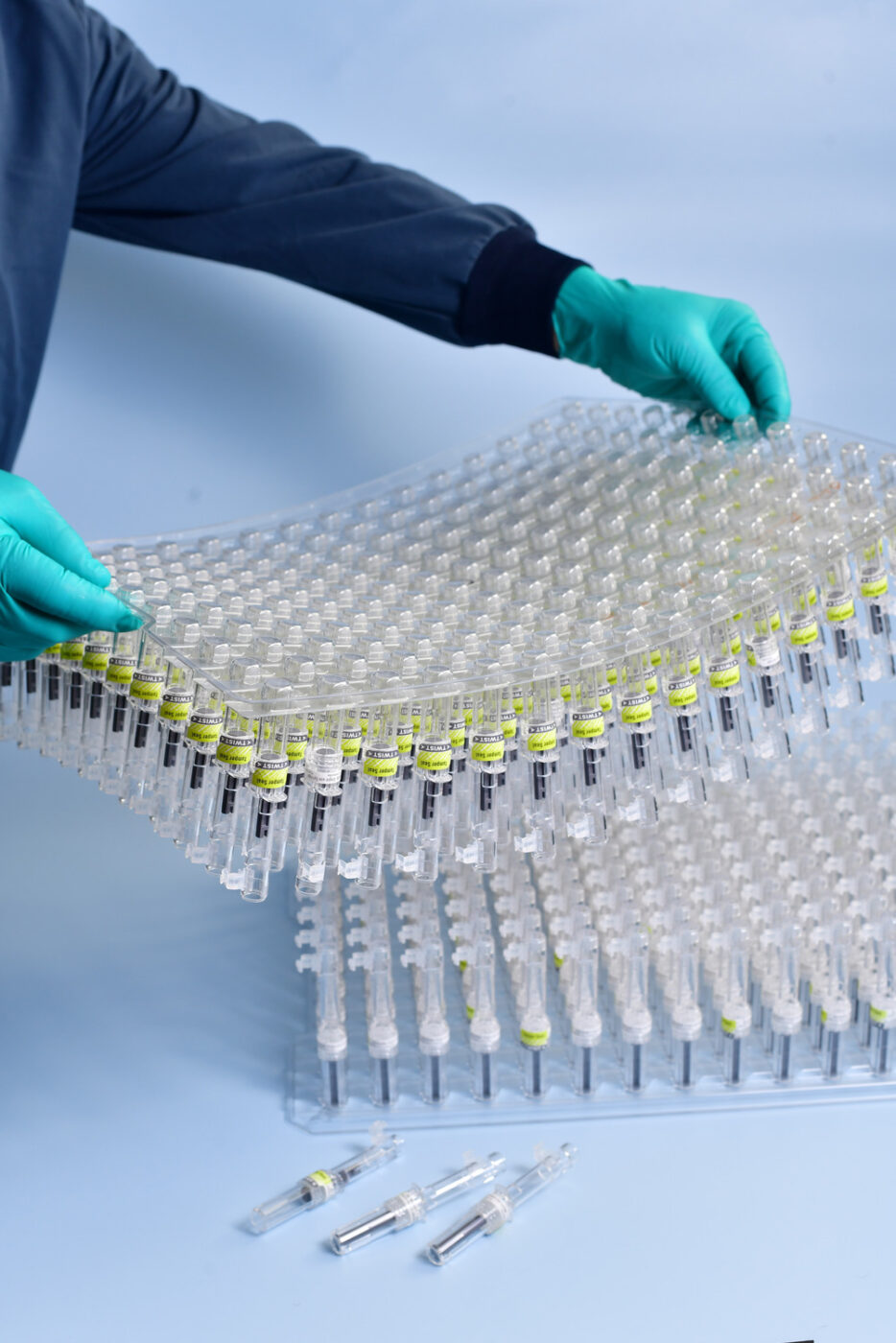

In the fast-paced world of healthcare and pharmaceuticals, thermoformed automation trays, also…

As important as oxygen is to sustaining life, it’s one of the biggest contributors to food spoilage. A chemically and biologically reactive compound, oxygen accelerates the growth of microorganisms responsible for mold, yeast, and other harmful fungi. To prevent food spoilage and keep products fresh, food industry packaging experts turn to various flexible packaging solutions.

There are two main types of flexible packaging used to limit oxygen exposure and extend a food product’s shelf life.

1. MAP (Modified Atmosphere Packaging)

A packaging process also known as “gas flushing,” MAP replaces the oxygen inside the empty space of a package with a different gas — usually nitrogen or a nitrogen-carbon dioxide mixture. This is a popular method for dried fruit, nuts, shredded cheese, potato chips, and similar snacks.

A packaging process also known as “gas flushing,” MAP replaces the oxygen inside the empty space of a package with a different gas — usually nitrogen or a nitrogen-carbon dioxide mixture. This is a popular method for dried fruit, nuts, shredded cheese, potato chips, and similar snacks.

2. Vacuum Packaging

Rather than replacing the oxygen within a package, vacuum packaging use heat to seal the open ends shut. Once ends are sealed, the vacuuming process makes use of an air compressor to draw gas out of the packaging, either partially or completely; this is often used for fresh and processed meats and cheeses.

After air has been replaced or reduced through one of these methods, an oxygen barrier must be created to maintain a low internal oxygen concentration within the package. Poor seals without adequate oxygen barriers will give way to the oxygen partial pressure differential in the atmosphere, allowing oxygen to enter and countering any of the previously achieved benefits of MAP or vacuum packaging.

To measure and compare the oxygen barrier of different types of film materials, packaging experts refer to the oxygen transmission rate (OTR). Oxygen-barrier packaging materials with OTR values of < 1 cc/100 in2/24 hr (15.5 cc/m2/24 hr) are considered “high oxygen barrier” solutions.

Packaging solutions for the food industry, in particular, must account for the harmful effects of concentrated oxygen within a pack; understanding the different types of flexible packaging available to combat food degradation from oxygen exposure is critical to extending the shelf life of the product and protecting the health and safety of the customer.

Plastic Ingenuity offers packaging solutions for food-industry conglomerates – from napkin sketches to prototyping and testing to high-volume production and packaging automation equipment setup. Our Cross Plains facility is ISO 9001:2008 and SQF Level Three certified. For additional information about our food packaging services, download our eBook, “The Impact of Barrier Technology in Food Packaging.”