Understanding Packaging EPR: What Brands Need to Know Get up to speed…

Welcome to Plastic Ingenuity’s blog series on packaging polymers! In this series, we will explore the different types of polymers used in packaging and their properties, applications, and environmental impact. We will also discuss the latest developments in sustainable packaging and how the industry is evolving to meet the growing demand for circular solutions. Join us as we dive into our third installment in a seven-part series with material #3: PVC (Polyvinyl Chloride)

Polyvinyl chloride (PVC) is a type of plastic that is durable, versatile, and is a relatively low-cost option. PVC is clear, rigid, durable, and very easy to mold. The unique utility it offers packaging is its ability to weld to itself in a heat-sealing process.

Some examples of packaging applications that commonly use PVC include:

▪️ Clamshell packaging: PVC is commonly used to create clear, protective clamshell packaging for a variety of products, including electronics, toys, and small household items.

▪️ Blister packaging: PVC is often used as the backing material for blister packaging, which is a type of packaging that consists of a plastic blister or bubble that holds the product and a paperboard backing.

▪️ Shrink wrap: PVC shrink wrap is a popular packaging option for a variety of products, including food, beverages, and consumer goods.

▪️ Food packaging: PVC is commonly used in food packaging applications, including meat, cheese, and bakery products.

▪️ Healthcare packaging: PVC is used in a variety of healthcare packaging applications, including IV bags, blood bags, and medical tubing.

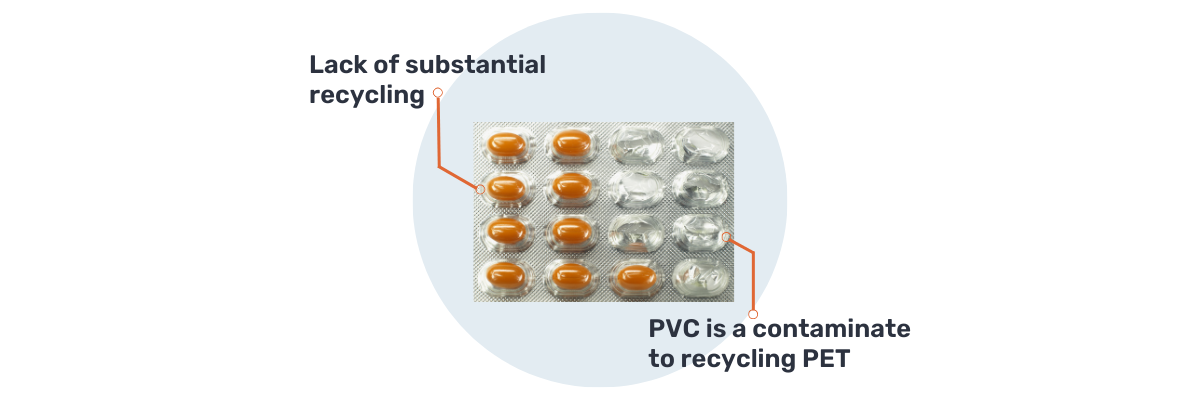

Lack of substantial recycling is the main drawback of using PVC. It is not commonly collected for recycling and markets for post-consumer PVC material are non-existent. In fact, PVC is considered a contaminate to PET recycling.

A PVC package looks identical to a PET package on a manual sorting line. If too many PVC packages are sorted into a PET bale, it can cause issues with recycling the PET. Therefore, the impact on PET recycling and potential health concerns have led many organizations to eliminate PVC from their packaging portfolios, and alternatives.

PET is a common replacement for PVC. However, there are some properties that are difficult to replace. PETG can be an option for packages that are welded together but that material has recycling challenges as well.

It’s important to note that while PVC is a popular packaging material, it also has some drawbacks, such as concerns about its environmental impact and potential health risks associated with exposure to PVC chemicals. As a result, some companies and industries are moving towards more sustainable packaging materials. For more information about sustainability in the plastics industry, visit www.plasticingenuity.com/sustainability