Understanding Packaging EPR: What Brands Need to Know Get up to speed…

Welcome to Plastic Ingenuity’s blog series on packaging polymers! In this series, we will explore the different types of polymers used in packaging and their properties, applications, and environmental impact. We will also discuss the latest developments in sustainable packaging and how the industry is evolving to meet the growing demand for circular solutions. Join us as we dive into our fifth installment in a seven-part series with material #5: PP (Polypropylene)

PP (polypropylene) is a versatile plastic material that is commonly used in packaging applications due to its excellent properties. PP has the lowest density of any solid polymer used for packaging. It has an ideal blend of physical properties, like rigidity and impact strength. PP can be clarified for use in applications that need a clear substrate. PP can be refrigerated and microwaved without losing its integrity.

Here are some of the common PP packaging applications:

▪️ Food packaging: PP is commonly used for food packaging because it is a non-toxic, lightweight, and durable material that can withstand high temperatures. PP food packaging includes containers, cups, bottles, and bags.

▪️ Healthcare packaging: PP is used in healthcare packaging applications such as pill bottles, medical trays, and syringes because it is resistant to chemicals, sterilization, and moisture.

▪️ Consumer goods packaging: PP is commonly used in the packaging of consumer goods such as cosmetics, toys, and electronics due to its excellent clarity, stiffness, and durability.

▪️ Industrial packaging: PP is also used in industrial packaging applications such as bulk bags, shipping sacks, and pallet wraps because it is strong and can withstand harsh environmental conditions.

▪️ Agricultural packaging: PP is used in agricultural packaging applications such as greenhouse films, bale wraps, and seedling trays because it is resistant to UV radiation and can withstand extreme temperatures.

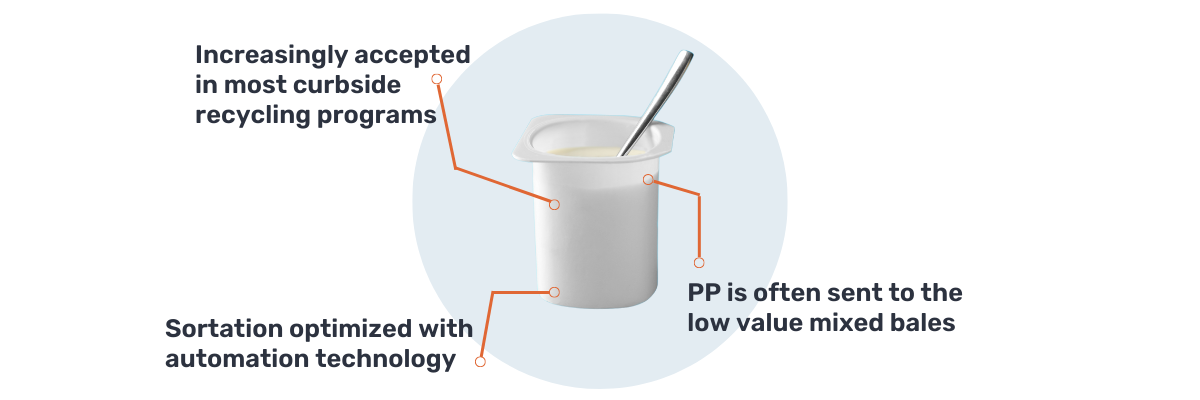

PP does get recycled but at lower rates than other polymers we’ve chronicled. About 500 million pounds gets recycled every year but that’s only 14% of the overall rigid PP market. This lower recycling rate is due to PP’s utilization in a wide array of applications making it difficult to identify and sort on manual sort lines. Many recyclers send PP items into low value mixed bales if they don’t have the ability to sort properly and efficiently.

Automated sorting can help identify PP materials where a human eye cannot. The adoption of this equipment is increasing, in part because of grants from The Recycling Partnership’s PP Recycling Coalition. Today, most PP rigid containers were recently upgraded to “widely recycled” in the How2Recycling program due to the increase in PP recycling access.

Recycled PP can be made into new packaging items, like paint cans. A significant amount gets consumed in the durable goods industry for items like lumber and furniture.

For more information about sustainability in the plastics industry, visit www.plasticingenuity.com/sustainability