Understanding Packaging EPR: What Brands Need to Know Get up to speed…

Welcome to Plastic Ingenuity’s blog series on packaging polymers! In this series, we will explore the different types of polymers used in packaging and their properties, applications, and environmental impact. We will also discuss the latest developments in sustainable packaging and how the industry is evolving to meet the growing demand for circular solutions. Join us as we dive into our sixth installment in a seven-part series with material #6: PS (Polystyrene)

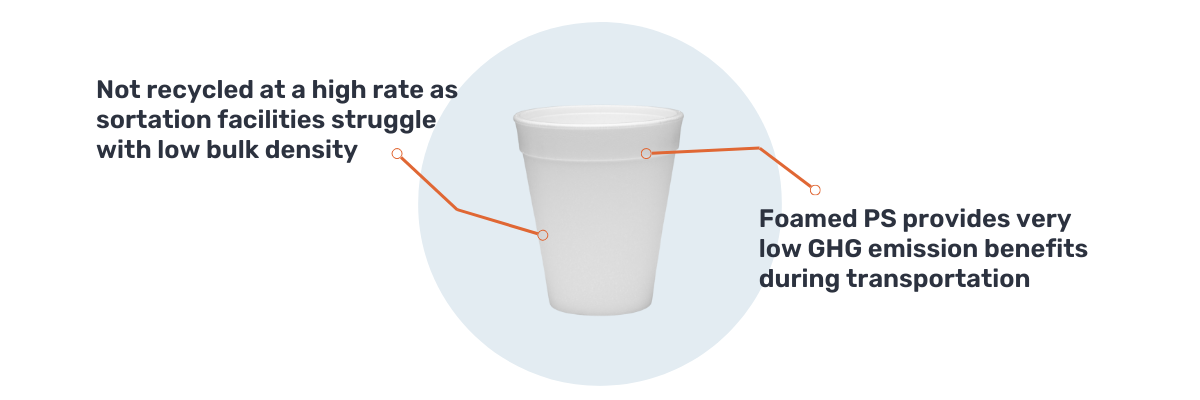

Polystyrene packaging is a popular choice for protecting and cushioning products during transportation and storage either in foam or solid formats. Polystyrene foam, also known as EPS (expanded polystyrene), is lightweight and has excellent shock-absorbing properties, making it ideal for use in packaging applications. PS has the lowest density of any polymer used for packaging when foamed. The lightweight nature of foamed PS leads to greenhouse gas emission benefits during transportation.

Some common applications of polystyrene packaging include:

▪️ Electronic and electrical goods packaging: Polystyrene foam can be molded to fit the shape of electronic and electrical goods such as computers, TVs, and appliances, providing excellent protection during shipping.

▪️ Food and beverage packaging: Polystyrene foam is often used to package and insulate food and beverages such as meat, fish, fruits, and vegetables, as well as hot and cold beverages.

▪️ Pharmaceutical and medical packaging: Polystyrene packaging is widely used in the pharmaceutical and medical industries to protect sensitive medical equipment, devices, and supplies during shipping and storage.

▪️ Automotive and transportation packaging: Polystyrene foam is used to protect automotive parts and components during transportation and storage.

▪️ Industrial packaging: Polystyrene foam is also used in industrial packaging applications to protect fragile or sensitive equipment, machinery, and parts during shipping and storage.

The main drawback of PS is that it is not currently recycled at a high rate. 35 million lbs. get recycled on an annual basis. That is about 3% of the production volume. Foamed PS is very difficult to handle at the sortation facilities and by recyclers because of its extremely low bulk density. Many curbside recycling programs prohibit PS in their collection bins.

Organizations are turning to advanced recycling methods to recycle PS. Those technologies could play a key role in increasing PS recycling. Recycled PS can be made into new packaging items, like plant seedling trays. A significant amount gets consumed in the durable goods industry.

While polystyrene is an excellent choice for packaging applications, it is important to note that it is not as environmentally friendly as other polymers, compelling companies to explore alternative packaging materials that are more sustainable promote circularity.

For more information about sustainability in the plastics industry, visit www.plasticingenuity.com/sustainability