Understanding Packaging EPR: What Brands Need to Know Get up to speed…

Welcome back to PI Circular! In this edition, we will take a deep dive into the current state and outlook for Polypropylene recycling.

There is a lot of activity and excitement surrounding polypropylene (PP) recycling. Most recently, the How2Recycle program upgraded most rigid PP containers from “Check Locally” to “Widely Recycled” in the U.S. Achieving this milestone is a direct result of the impact of The Recycling Partnership’s Polypropylene Recycling Coalition. These efforts bolster a post-consumer stream that will significantly alter the recycling landscape, positively affecting the rigid thermoforming industry.

Plastic Ingenuity is proud to be current funding partners of the Polypropylene Recycling Coalition, spearheading this effort to increase PP curbside recycling. The group’s primary focus is to unlock the environmental and economic benefits of residential recycling and a circular economy.

PP Recycling Challenges and Opportunities

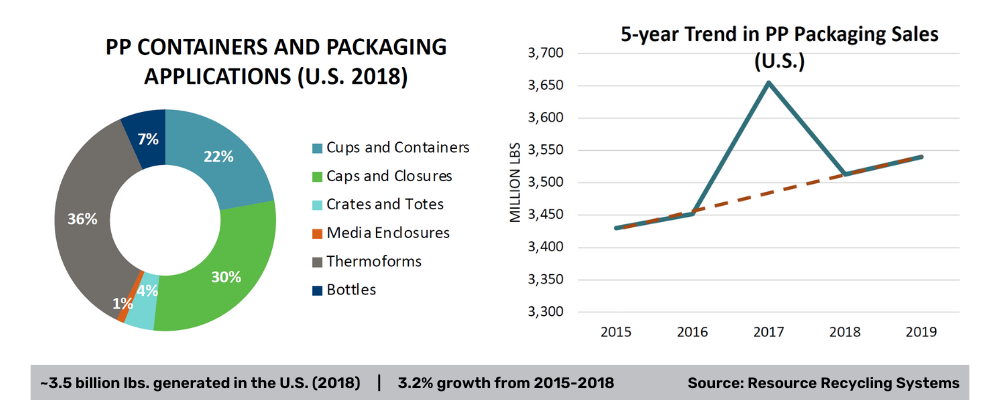

Understanding the challenges of recycling PP in comparison to its PET and HDPE counterparts is paramount to identifying potential solutions. According to Resource Recycling Systems (RRS), approximately 3.5 billion pounds of rigid PP packaging is sold in the U.S. every year, with the majority comprising of thermoform applications, as depicted in the graphs below.

PP packaging applications are diverse in format, shape, and size. Applications for PP in packaging are nearly endless: PP can be thermoformed into a cup or tray, blow molded into a bottle, injection molded into a container or 5-gallon pail. This diversity makes PP items more complicated to sort and process than other resins with more homogeneous formats, like PET beverage containers or HDPE milk jugs. This challenge is particularly impactful for sortation process dependent on manual sortation methods, rather than near infrared (NIR) or optical automation.

Additionally, past reliance on export markets for recovered plastic waste often resulted in PP being included in mixed plastic bales rather than sortation into PP bales. This export factor hindered the development of a robust market for PP reclamation.

The demand for recycled Polypropylene (rPP) is growing in high value packaging markets, such as food grade rPP. Currently, there is very little food grade rPP produced, but the demand exists, and PP reclaimers are responding by investing in capabilities and filing for FDA No Objection Letters (NOLs).

Growth Projections and Investments

Substantial investment is being made to grow PP recycling, ultimately improving the quantity and quality of recovered PP. Increasing demand is driving higher value recycling markets and recycled content. This is due to strategic investments and technological advancements including:

– Investments: Grants from The Recycling Partnership PP Recycling Coalition $6.7M

– Sortation: Technologies like artificial intelligence (AI) & robots address PP sortation challenges

– Reclamation Capacity: PP reclamation capacity growing

– Quality: 5 new FDA No Objection Letters filed in 2022 to produce food grade rPP compared to 8 the previous 5 years (2017-2021)

– End Markets: Brands are demanding recycled content and requiring progress reporting to meet US Plastic Pact and other commitments

– Advanced Recycling: Investment and commercialization of new reclamation technologies like PureCycle open the door to reclaiming hard-to-recycle formats to produce rPP with virgin like properties

– Innovation: Digital watermarks and fluorescent markers on packaging have the potential to unlock infrared (NIR) detection and sortation advancements

The PP recycling landscape is evolving rapidly. Recent accomplishments prove that sustainable progress toward increased circularity is possible through thoughtful and extensive collaboration.

Have you been following our Good Information video series? The mission of “Good Information” is to provide a concise understanding of a topic related to circularity. We recently launched a series of videos related to polymers commonly used in packaging. Please enjoy our #5 Polypropylene video by visiting the link below and feel free to share!

California recently became the 4th state to pass an Extended Producer Responsibility bill: EPR Bill in California Signed (Waste 360). The bill will require all plastic packaging in the state to reach a recycling rate of 30% by 2028 and 65% by 2032. The bill also sets a source reduction target for plastic packaging of 25% by 2032. Producers that sell the subject items in the state must join a Producer Responsibility Organization (PRO) by January 1st, 2024. The PRO must submit a plan on how the targets will be achieved to CalRecycle for review.

In related news, California Governor Gavin Newsom vetoed a bill which would have imposed PCR minimums for thermoform food containers sold within the state: Waste Dive. Newsom cited potential conflicts with the EPR bill as his justification for the veto.

Our very own President, Dan Kuehn, and Sustainability Champion, Zach Muscato, were recently interviewed by Georgie Frost for Business Reporter. They shared their thoughts on how plastic thermoforms can be a sustainable packaging choice. See the full interview HERE.

Grants provided by the PP Recycling Coalition to support PP recycling efforts.

People positively affected by the grants.

Annual additional pounds of PP recovered for domestic end markets.

We look forward to attending the APR Member Meeting in Austin, TX on November 9-11th. The meeting is a fantastic forum for CPGs, packaging creators, and recyclers to collaborate on efforts to advance recycling.