Understanding Packaging EPR: What Brands Need to Know Get up to speed…

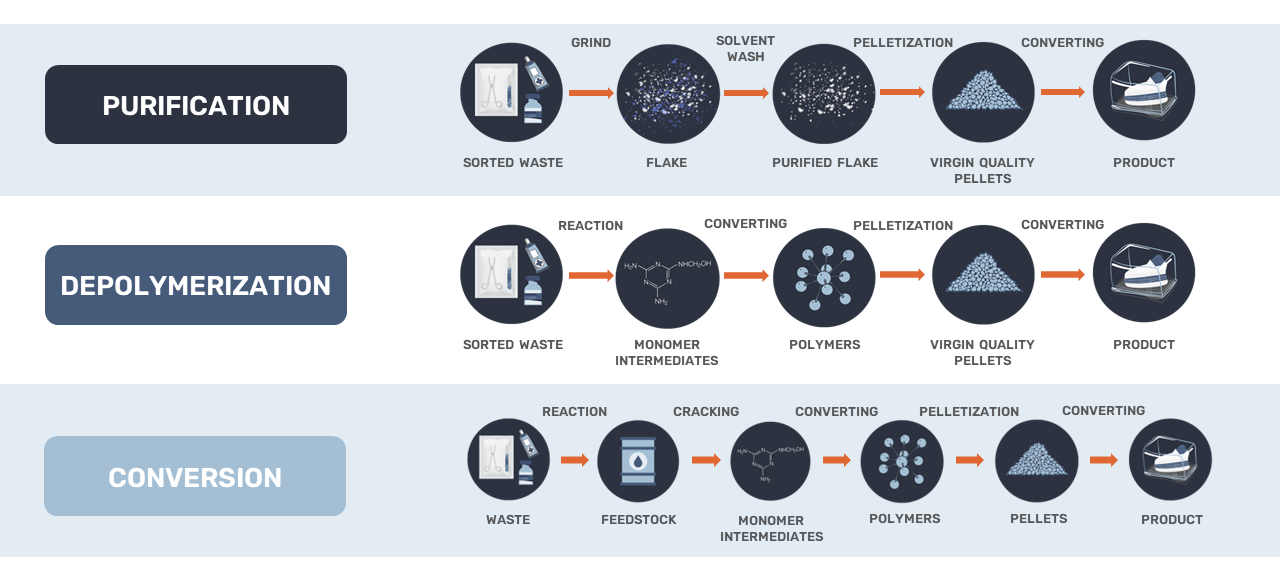

Welcome back to PI Circular! In this edition, we will discuss the basics of mass balance for materials derived from advanced recycling. Advanced recycling technologies, like purification, depolymerization, and conversion, are poised to transform plastic waste recycling. Focusing on hard-to-recycle items, like textiles and mixed material films, advanced recycling techniques turn back the clock on plastic waste by converting it back into its basic building blocks. As illustrated in the chart below, the outputs of the advanced recycling process can then be converted to resin for use in new products.

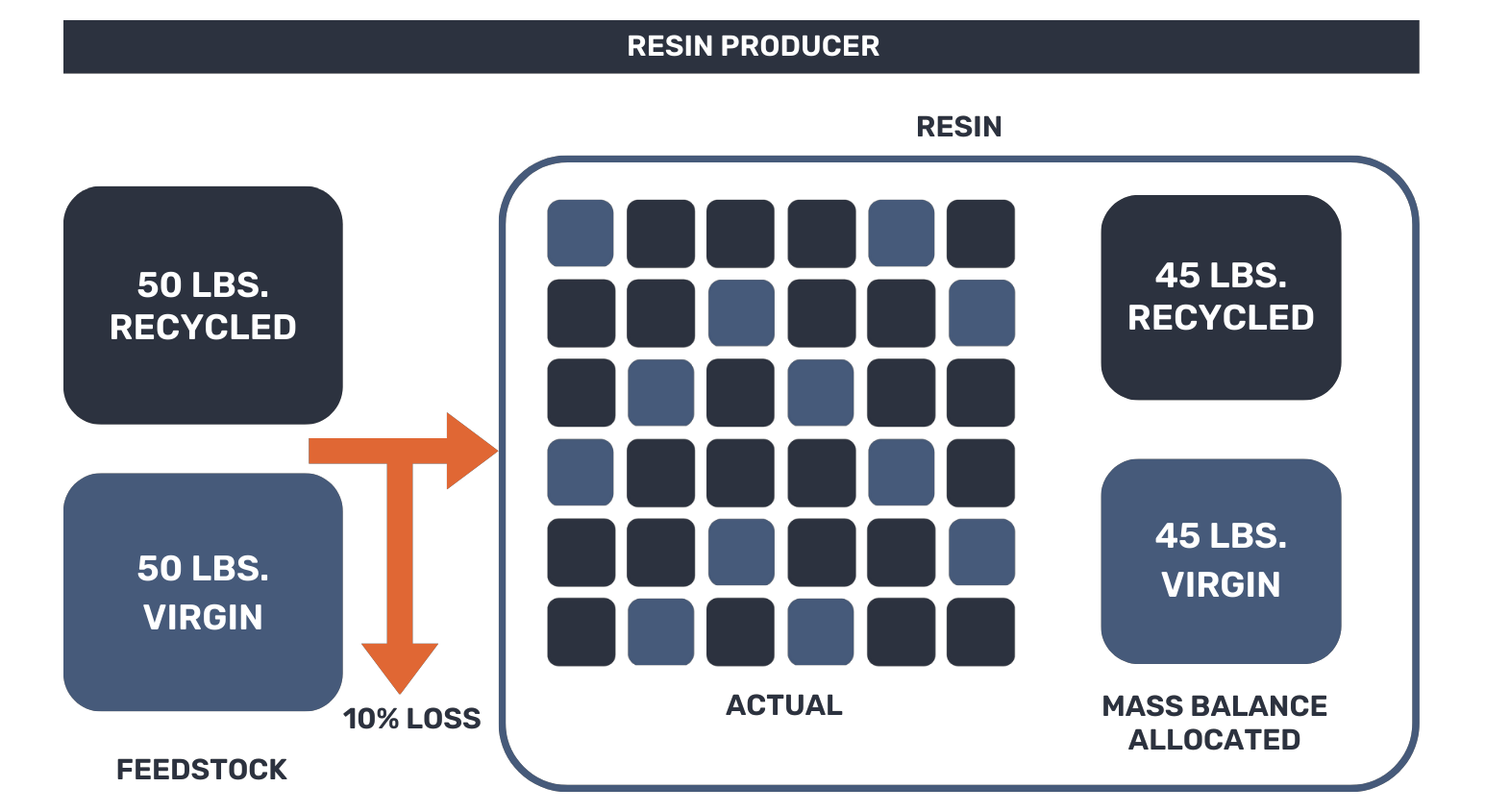

Mass balance is a crucial component to ensuring credibility when incorporating advanced recycled materials into a manufacturing process. Feedstocks derived from advanced recycling processes are typically blended with feedstocks derived from fossil fuels during the plastic resin manufacturing process. Since feedstocks derived from advanced recycling are nearly identical to fossil fuel-derived feedstocks, physical segregation of recycled content is not practical. The mass balance approach provides a credible and verifiable solution for tracing sustainably sourced materials throughout a complex value chain. Mass balance is a chain of custody system designed to track the total amount of content in scope through a product system to ensure the appropriate allocation of this content to the finished goods based on auditable bookkeeping.

The International Sustainability and Carbon Certification (ISCC) PLUS is an internationally recognized certification of compliance with robust environmental, social, and traceability requirements.

ISCC PLUS establishes traceability in global supply chains for circular and bio-based materials. The ISCC PLUS system is based on the mass balance approach, which ensures the conservation of the certified content throughout the value chain. The mass balance approach is used to track raw materials from their origin through to the final product, ensuring that the amount of sustainable content that has been used is accurately recorded. The approach aims to seamlessly integrate advanced recycled technologies into existing production assets. Under the mass balance approach, the entire supply chain is considered, from the raw materials, through the production processes, and to the finished products.

Incorporating a mass balance approach enables companies to integrate sustainable raw materials, like those derived from advanced recycling processes, seamlessly into existing processes and assets. Without this approach, companies would need to duplicate infrastructure, increasing timelines, costs, and emissions. Mass balance is the key to rapidly scaling sustainable material integration and credibly driving circularity.

PI’s facilities in Cross Plains, WI and Mazomanie, WI are ISCC PLUS certified. The certificates can be accessed on our website: ISCC PLUS Certificate

PETG is used extensively in healthcare packaging. PETG plays an essential, and irreplaceable, role in the protection of sensitive sterile medical devices. Learn more about PETG in the following installment of Good Information, Packaging Polymer Series:

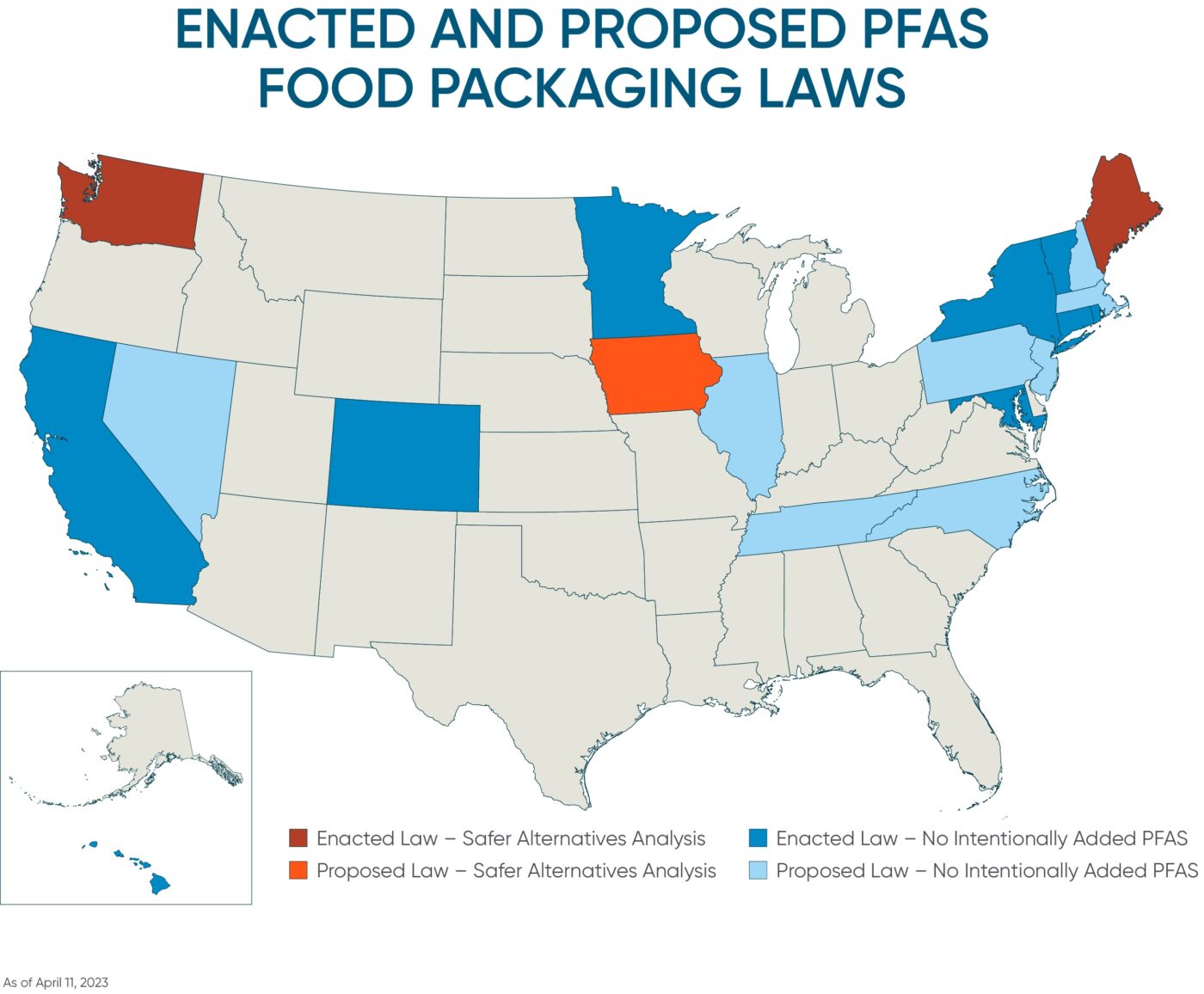

Eliminating “Materials of Concern” from packaging is a critical focus of many healthcare and food organizations. PFAS, also known as forever chemicals, are under the microscope given their potential impact on human health. Examples of PFAS in packaging are coatings added to fiber-based packaging to protect the fibers from moisture and grease. Twenty states have either passed or proposed legislation regulating the use of PFAS in specific types of packaging. The definition of “packaging” as detailed in the legislation is critical to understanding potential impacts. Some states, like California, have limited the definition to plant or fiber-based food packaging. The following article from BCLP provides an excellent overview: PFAS Update: State Regulation of PFAS in Food Packaging.

Our sustainability expert, Zach Muscato, discussed his perspective on healthcare packaging sustainability. The article can be found here: Q&A: Thermoformer Talks Basics of Sustainability in Healthcare Packaging.

Attending the Sustainable Packaging Coalition’s Advance event this September in Boston? Don’t miss our participation on a panel of experts about Designing and Developing Sustainable Healthcare Packaging. Click here to register if you are a member of SPC.