Polypropylene (PP) is a highly versatile and lightweight plastic widely used in packaging. Its exceptional durability and adaptability make it a staple across diverse industries. This post explores PP’s key features, its recycling challenges, and the latest innovations enhancing recovery processes.

What is Polypropylene (PP)? Key Characteristics

PP’s flexibility allows it to take on various forms and colors, making it an essential material in packaging. Some common applications include:

- Thermoformed cups and trays: Ideal for food service and storage.

- Injection-molded containers: Used in cosmetics, food, and household products.

- Blow-molded bottles: A popular choice for beverages and cleaning solutions.

- Form-fill-seal packages: Essential for products needing high durability.

PP’s adaptability makes it indispensable in industries such as food and beverage, healthcare, household cleaning, and cosmetics.

Challenges in PP Recycling

The widespread use of PP presents hurdles in recycling, particularly due to its varied formats, sizes, and colors. Unlike standardized materials like PET bottles, PP’s lack of uniformity complicates sorting and collection processes.

Historically, PP was lumped into mixed plastic bales with other plastics, such as PVC and LDPE. However, China’s National Sword policy in 2018 redirected the focus to domestic recycling efforts. A 2020–2021 study by the Sustainable Packaging Coalition (SPC) revealed a 59% national acceptance rate for PP tubs and containers, which subsequently earned a “check locally” status under the How2Recycle program.

Advancements in Polypropylene Recovery

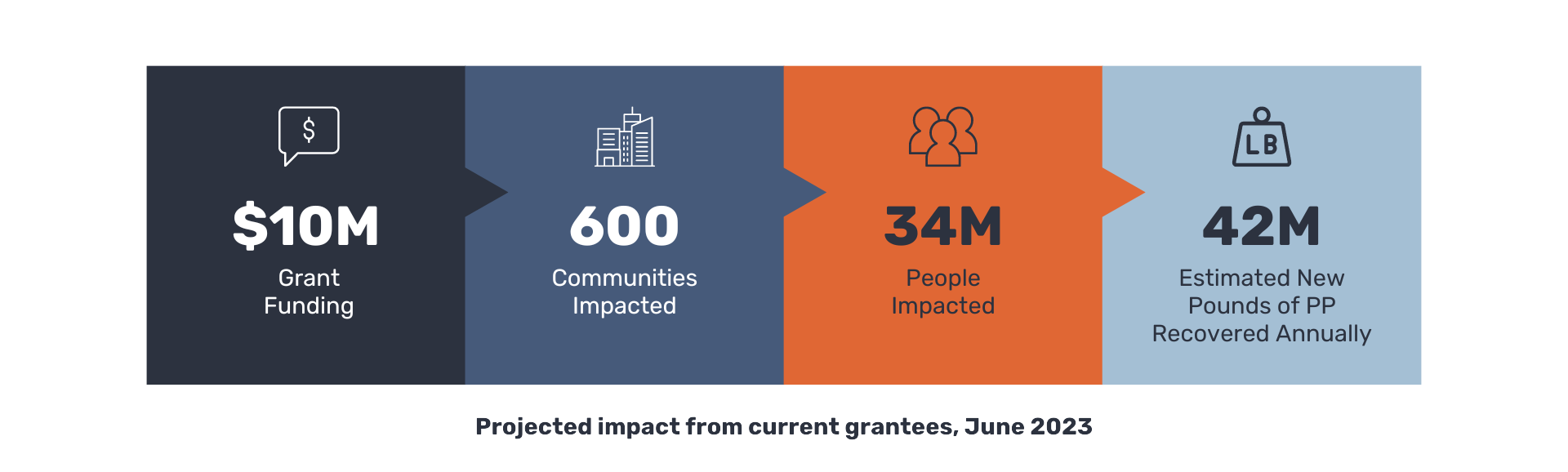

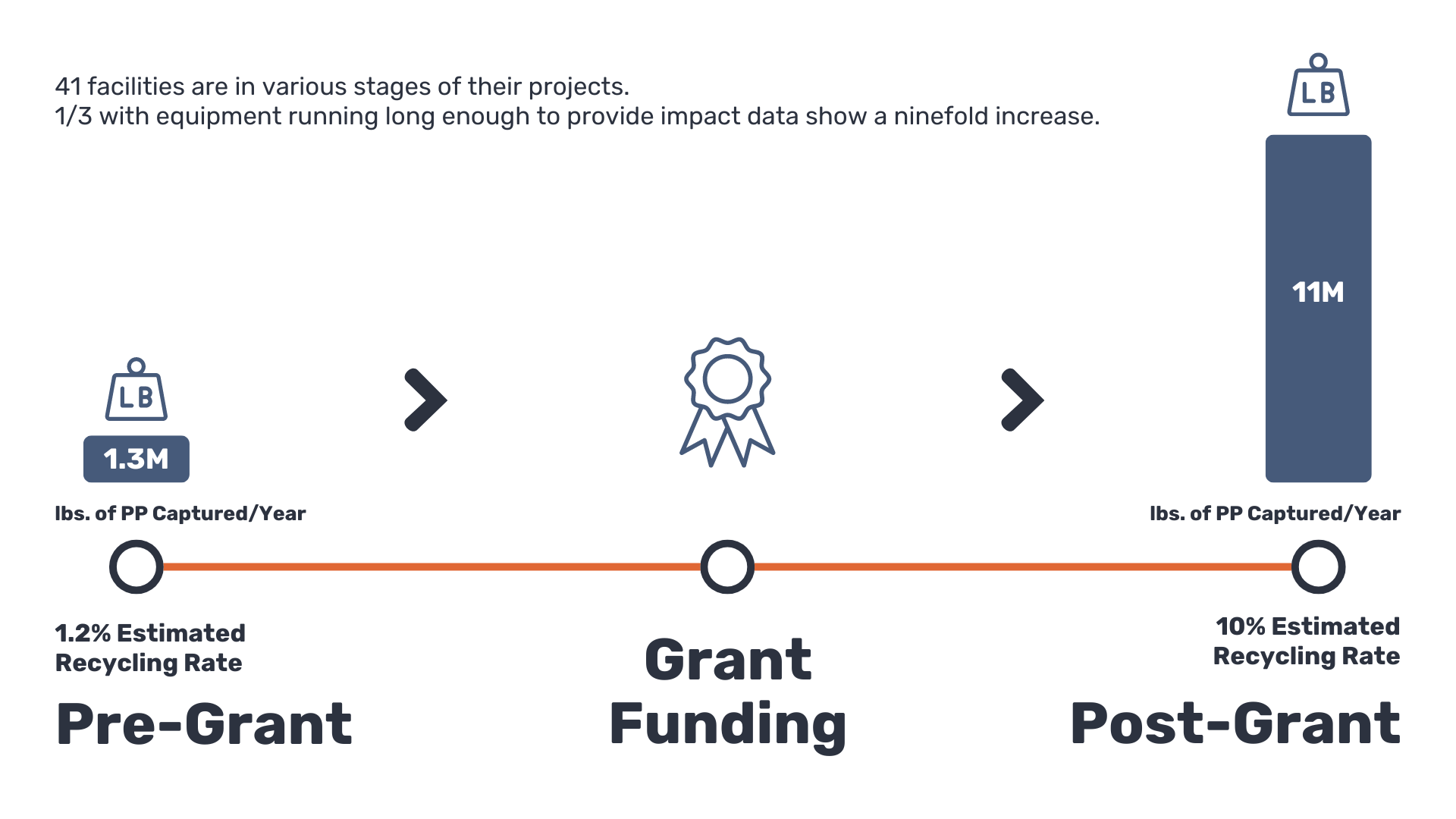

Efforts to overcome recycling challenges have gained momentum. The Recycling Partnership launched the Polypropylene Recycling Coalition in 2020, with support from organizations like Plastic Ingenuity. Through grants and strategic initiatives, the coalition has improved PP recovery infrastructure in over 600 communities and 41 material recovery facilities (MRFs).

By 2022, collaborative studies from SPC and The Recycling Partnership confirmed a 65% access rate for PP recycling nationwide. This milestone reinstated PP’s “widely recyclable” status, supported by emerging domestic end markets.

The Environmental Impact of Enhanced PP Recycling

Did you know U.S. households generate more than 2 billion pounds of PP annually? Recovering just 30% of this volume could supply over 600 million pounds of recycled PP and cut greenhouse gas emissions by 311,000 metric tons of CO₂.

Take Ohio as an example—through coalition-backed initiatives, household access to PP recycling surged from 34% to 69%. Facilities like Rumpke Waste & Recycling’s MRFs in Columbus and Cincinnati are now recovering over 1 million pounds of PP annually.

What Lies Ahead for Polypropylene Recovery?

Despite being the third most common material in residential recycling bins, PP still faces sorting limitations. Continued investments in technology, infrastructure, and collaborative efforts will be crucial to strengthening its recycling pipeline. These advancements are key to supporting a robust circular economy, where PP contributes both environmental and economic value.

How You Can Help Whether you’re in packaging or just interested in sustainability, supporting advancements in polypropylene recovery helps create a greener, more sustainable future. Let’s work together to unlock the full potential of PP!