Medical device packaging requirements in the U.S. are rigorous. And it makes…

Healthcare

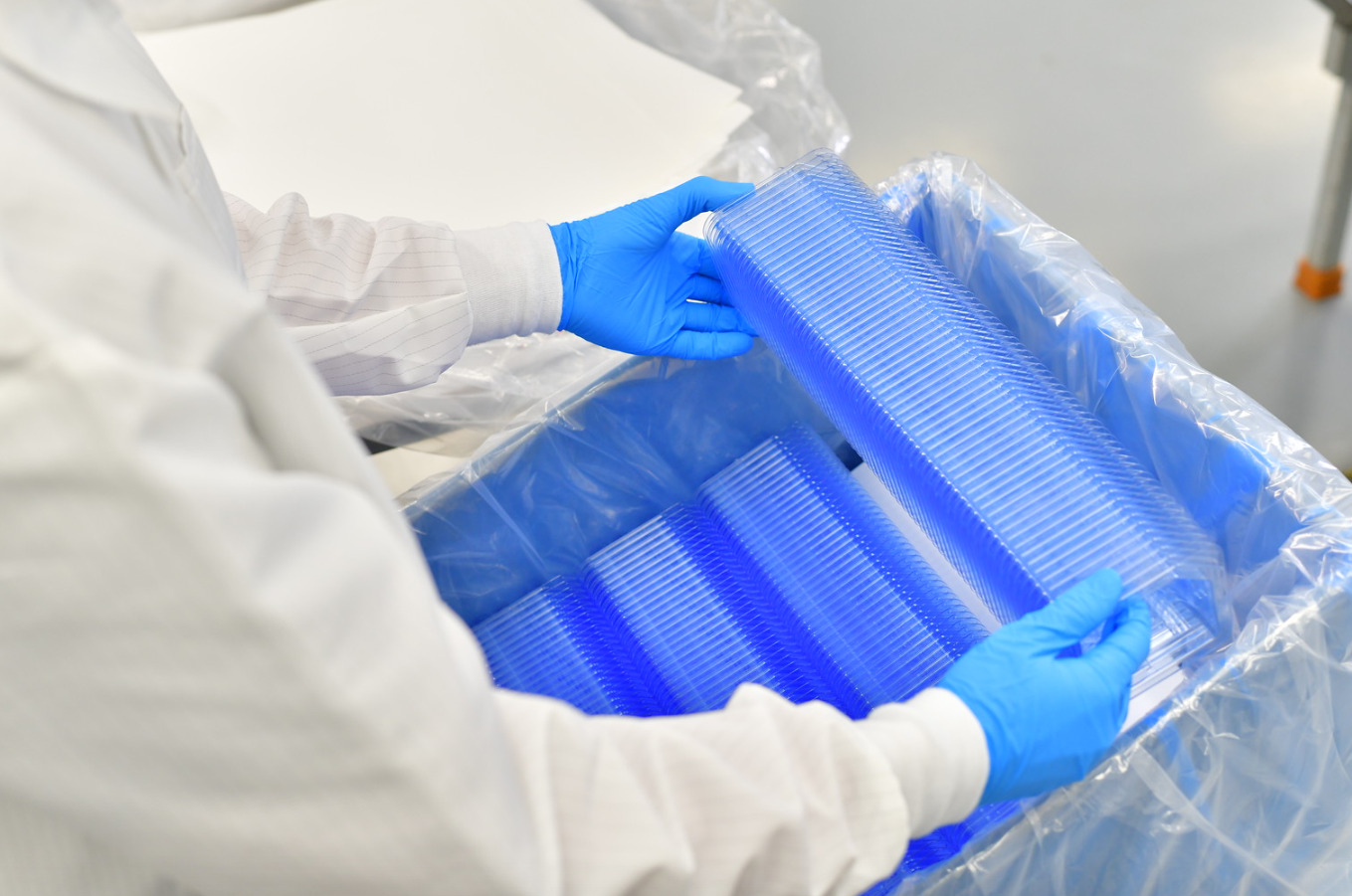

We create innovative, scalable thermoformed solutions that accelerate product development, simplify manufacturing processes, and empower the world’s leading healthcare brands to bring new therapies to market as quickly and efficiently as possible. From innovation to integration to industrialization, our solutions go beyond thermoforming.

The healthcare market relies on your solutions, and you should be able to rely on your thermoforming partner to understand requirements, work quickly, and remain flexible to scale or expand your product as needed.

With deep knowledge of evolving requirements, a pulse on industry trends, technical expertise, and operational know-how, we create thermoformed solutions that deliver more to the healthcare market.

With vertical integration and total process control, we provide our healthcare customers a competitive edge by getting medical devices, drug therapies, and diagnostic products to market faster, always with patient safety and compliance top-of-mind.

We’re an extension of your team. From project management to technical support, our commercial team creates a best-in-class customer experience. Plus, our focus on value chain partnerships enables us to deliver end-to-end solutions and services to ensure your project’s success.

We understand the regulatory rigor, critical-to-quality product attributes, and seamless integration required to serve the healthcare market. By investing in continuous improvement and a quality-first culture, we are committed to exceeding the most stringent Quality and Regulatory standards.

This certification enables the use of circular plastics from advanced recycling technologies.

There’s opportunity within the healthcare market to create sustainable packaging solutions while still keeping patient safety and usability top of mind. Our circularity experts offer consultation to clients like you to create solutions that are as beneficial to clinicians and patients as they are to the planet.