Understanding Packaging EPR: What Brands Need to Know Get up to speed…

Picture this: A patient forgets to refill their blood pressure medication and receives a text reminder based on technology in the pill bottle itself. Another patient uses their smartphone to scan a QR code on their medical device packaging, which links them to an instructional video and other resources. These scenarios may sound like science fiction, but recent technological innovations in the healthcare packaging industry have made them a reality.

The hottest trends in consumer healthcare packaging promote accessibility, safety, and sustainability. Manufacturers increasingly use digital tools like QR codes and radio frequency identification (RFID) to make healthcare products more educational and trackable. Better still, new eco-friendly plastics and manufacturing techniques protect the health of the Earth and patients simultaneously.

Keep reading to discover some of the top healthcare packaging trends in 2023.

Smart/intelligent packaging incorporates interactive technology to increase functionality and enable consumers to engage with health products in new ways. In other words, smart packaging goes beyond simply keeping medical devices and pharmaceuticals safe and sterile. These materials also help patients monitor product safety and adhere to medication regimes.

Here are three examples of smart medical packaging:

Active packaging is another trend that falls under the umbrella of smart packaging. Manufacturers use tools like oxygen scavengers to help health products stay fresh and sterile.

According to the Healthcare Plastics Recycling Council, American healthcare facilities produce 14,000 tons of waste daily. Plastic packaging and products make up approximately 20% to 25% of this waste, and most of these materials don’t get recycled. However, many packaging manufacturers are taking steps to address this environmental crisis with green materials and solutions.

For example, Plastic Ingenuity recently created a sustainable packaging solution for Merit Medical Systems, developing inflation devices for angioplasty procedures. These medical devices have many configurations, sizes, and tube lengths.

The Plastic Ingenuity team developed a bulk universal transport tray with Eastalite™ copolyester, a novel foamed polyethylene terephthalate glycol (PETG). This creative packaging allowed the company to transport 133% more inflation devices per pallet and reduced packaging material waste by 20,000 lbs annually.

Additionally, manufacturers can now use recyclable plastics like high-density polyethylene (HDPE) to produce packaging for medical devices, medications, and syringes. HDPE can get recycled into bottles, lumber, and other products.

Personalized medicine has emerged as another top trend of 2023. This method uses a patient’s unique genetic makeup, lifestyle, weight, and other factors to develop customized treatment plans. Manufacturers can support this personalized medicine by creating innovative packaging designs tailored to individual patients’ needs.

Customized Drug Delivery Systems

3D printing technologies enable manufacturers to create custom drugs in various doses, shapes, and sizes. Pharmaceutical companies may create polypills that combine multiple therapies into a single dose or produce sweet-tasting chewable medicines for pediatric patients.

Medicine packaging solutions can make it easier to deliver these customized prescriptions to patients. For instance, manufacturers can add customized instructions that specify how frequently patients should take their medication based on their providers’ instructions. Custom unit dose packaging like individualized blister packs can also make it easier for patients to take the correct dosage.

Incorporation of Patient-Centric Designs

Some manufacturers have also begun implementing patient-centric design into pharmaceutical packaging. For example, packaging with QR codes that link to educational videos or phone support lines can increase health literacy.

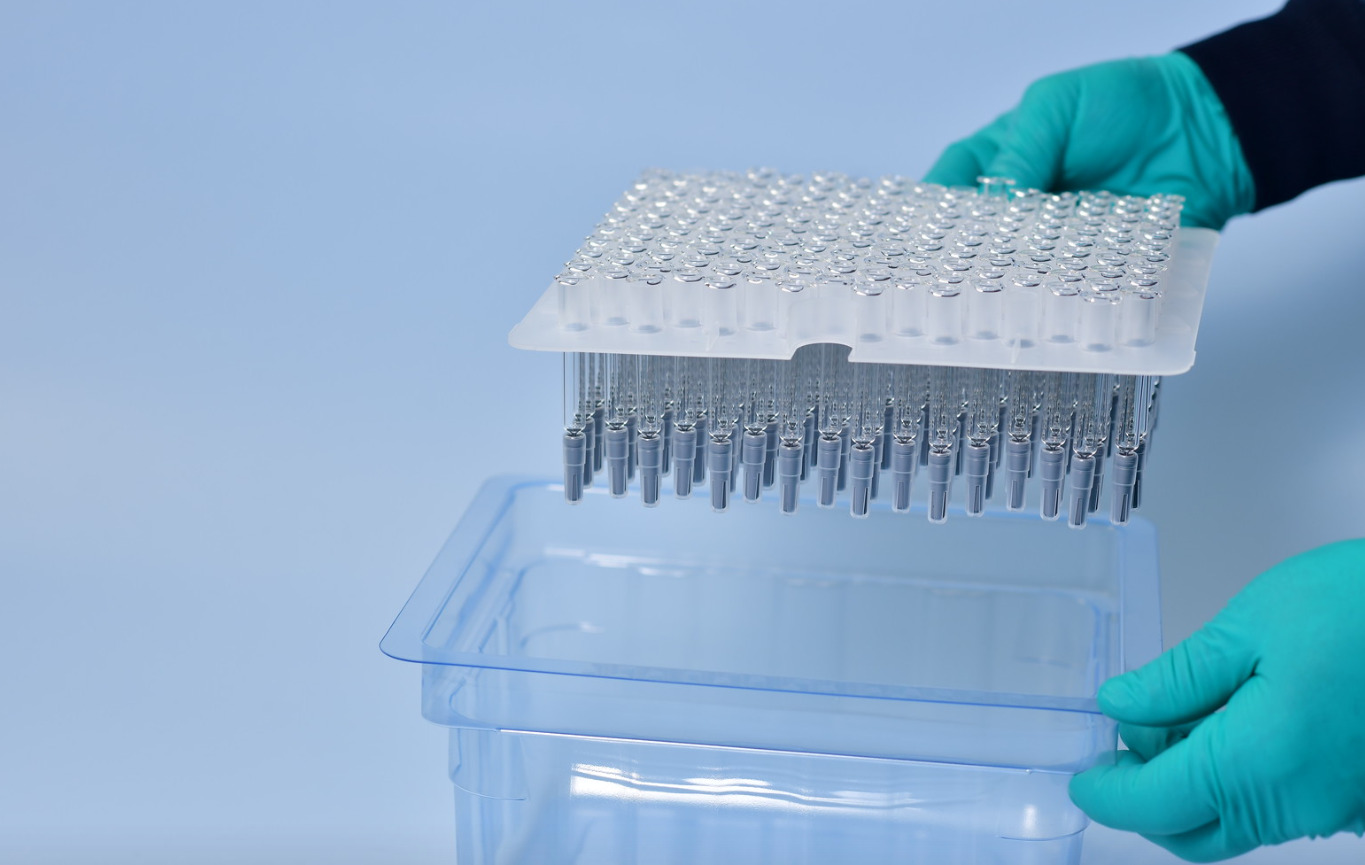

Advanced barrier systems are among the latest improvements to packaging in healthcare industries. These barriers protect sterile medical devices from germs and other contaminants.

Recent examples of advanced barrier packaging methods include:

Counterfeit medication and product tampering pose a serious risk to consumer health and reduce pharmaceutical companies’ revenue. Many patients mistakenly obtain counterfeit or tampered-with medication after ordering products from illegitimate online pharmacies.

Experts estimate that, to combat this growing problem, the global anti-counterfeit pharmaceutical packaging market will grow by 8.4% between 2022 and 2027. Manufacturers have developed medical packaging with innovative anti-counterfeiting and tamper-evident features, such as:

Recent innovations like blockchain technology and personalized medicine are revolutionizing the modern medical packaging industry. These changes have many benefits, from improving medication adherence to preventing counterfeiting. Additionally, these trends allow manufacturers to stand out from competitors and engage more consumers.

Plastic Ingenuity creates functional, informed packaging designs that implement groundbreaking practices and technology. We produce everything from common packaging configurations to unique packaging solutions that reflect the latest healthcare trends. Our expert team will help you develop the perfect packaging to enhance your product’s market presence.

Contact us today to learn how you can get started.